Guide to Masking Hooks

What are Industrial Hanging Hooks?

In this guide, we’ll cover what masking hooks are, how to use them, and how to choose the best type for your workflow.

Industrial Hanging Hooks, which are often referred to as Masking Hooks, are reusable wire hooks which are used to suspend components during finishing, painting, powder coating, drying or transport. They are most commonly made from durable mild steel or stainless steel and are available in various shapes such as "C", "S" and "V" Hooks.

Why Use Masking Hooks in Production?

Masking hooks are critical when you need to keep the coating surface untouched. With options like C hooks for powder coating, S shaped wire hooks, and custom-length hanging solutions, they:

Prevent blemishes causes by flat surfaces

Allow full 360° coating and drying

Improve part flow through production lines

Are reusable & reduce costs on single-use systems

Common applications for Masking Hooks

These hooks are widely used across industries such as:

- Powder Coating & Paint Shops – Suspending components cleanly for full coverage

- Electroplating – Dipping metal parts without surface contact

- Automotive Manufacturing – Organising parts for line assembly or curing

- Cleaning Lines – Suspending parts during ultrasonic or degreasing processes

- General Manufacturing – Hanging components pre- or post-treatment

- Conveyor movement – Select shapes that won’t swing or dislodge

- Reusability – Mild steel for general use, stainless steel for harsher chemicals or repeated cycles

Masking Hooks that We Stock

Each Hook type is available in various gauges and lengths depending on the desired weight capacity and hanging height.

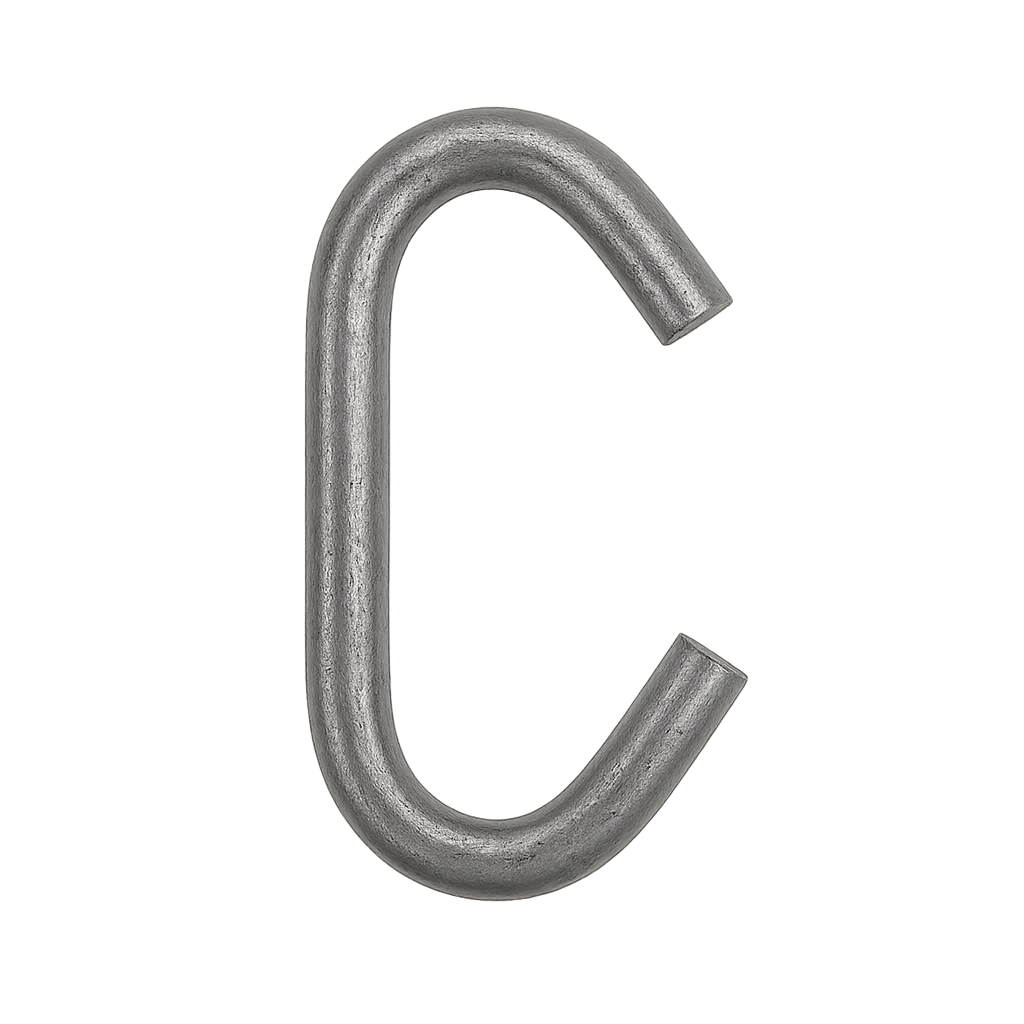

C Hooks

Our C Hooks are ideal for high-capacity hanging when spray painting; providing sturdy support for heavier parts during manual or automated spraying.

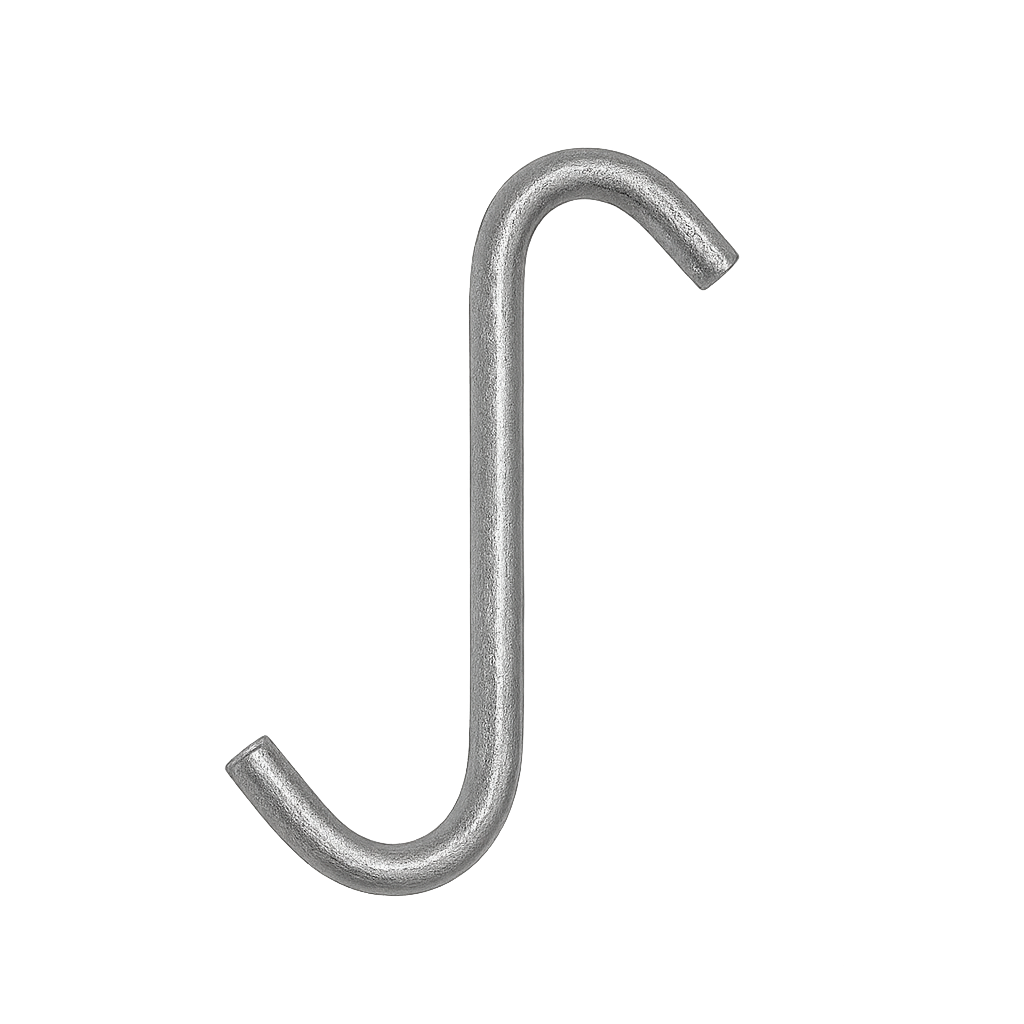

S Hooks

Our S Hooks are easy to attach and remove; they are ideal for applications in a range of industries due to their versatility.

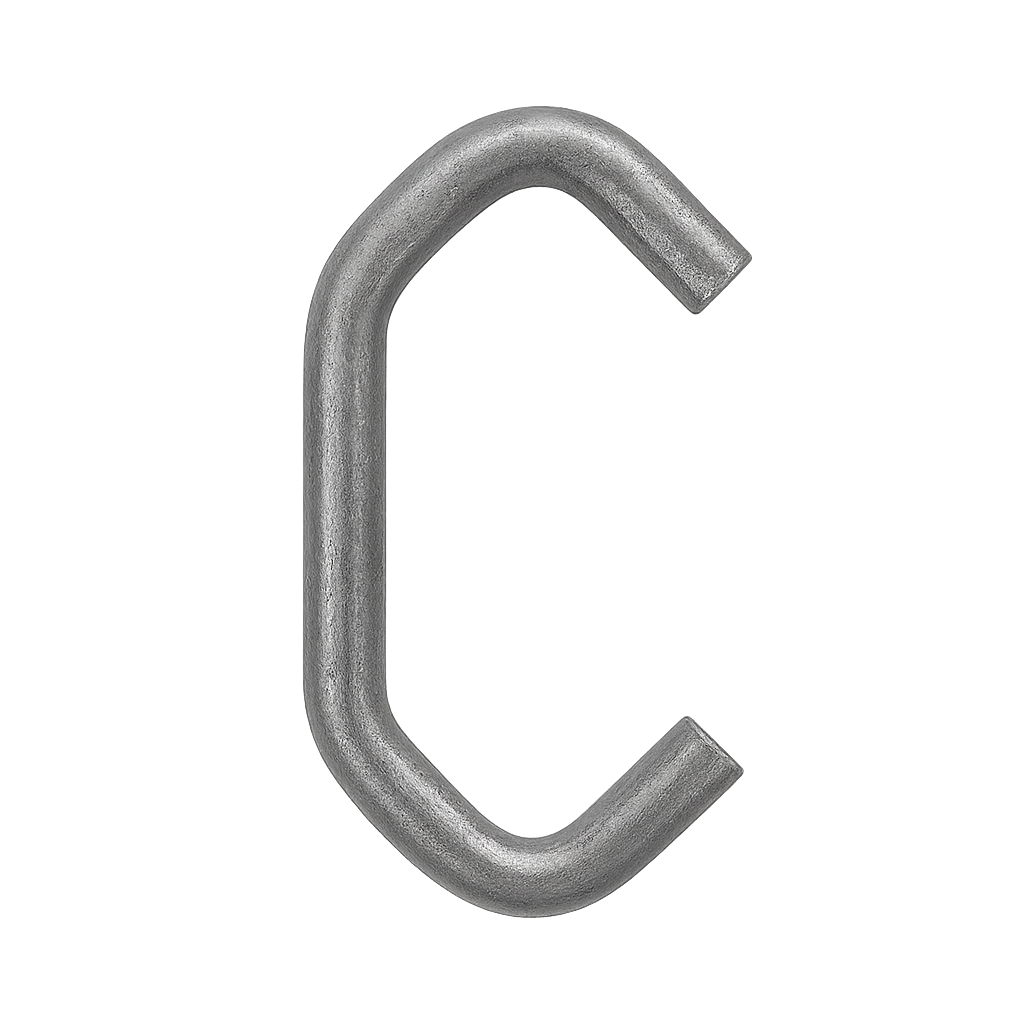

V Hooks

Our V Hooks are ideal for stabilising awkward parts during movement. They ensure full coverage due to having minimal contact points during Powder Coating, Painting or Anodising.

Related Products to Support Your Project

As a leading supplier of Powder Coating Hanging Systems UK, we offer a complete solution for both small businesses and industrial operators.

How to choose the correct Masking Hook for your application

Step 1: Identify the Part’s Weight

- Why it matters: Hooks must support the weight of the part without bending or breaking.

- What to do: Weigh the part and choose a hook with a safe working load that exceeds the part’s weight.

Step 2: Determine the Part’s Geometry

- Why it matters: The shape and size of the part affect how it can be hung.

- What to do: Look for holes, slots or edges which are suitable for hanging. Choose a hook shape (e.g., “C”, “V”, “S”, or custom) that fits securely without damaging the part.

Step 3: Consider the Coating Process Temperature

- Why it matters: Some hooks may deform or lose strength at high temperatures.

- What to do: Ensure the hook material (usually steel or stainless steel) is rated for the oven curing temperature (typically 180–220°C for powder coating).

Step 4: Ensure Good Electrical Contact (if grounding is needed)

- Why it matters: For electrostatic powder coating, the hook must provide a ground path.

- What to do: Avoid hooks with full insulation or coatings. Use bare metal hooks or those with contact points that pierce through masking.

Step 5: Evaluate Reusability and Cleaning

- Why it matters: Hooks accumulate overspray and may need cleaning or replacement.

- What to do: Choose robust hooks for long-term use. Consider disposable hooks for high-volume or low-cost parts.

Step 6: Match Hook Style to Rack or Conveyor System

- Why it matters: Hooks must fit securely into your existing hanging or conveyor system.

- What to do: Check the diameter and length of the hook stem. Ensure compatibility with rails, racks, or carriers.

Step 7: Test and Adjust

- Why it matters: Real-world testing ensures the hook performs as expected.

- What to do: Hang a sample part and run it through the process. Check for stability, grounding, and coating quality.

Can we help?

Our team can guide you on hook size, weight capacity, or build a tailored supply plan

CONTACT SALES

Leave a comment