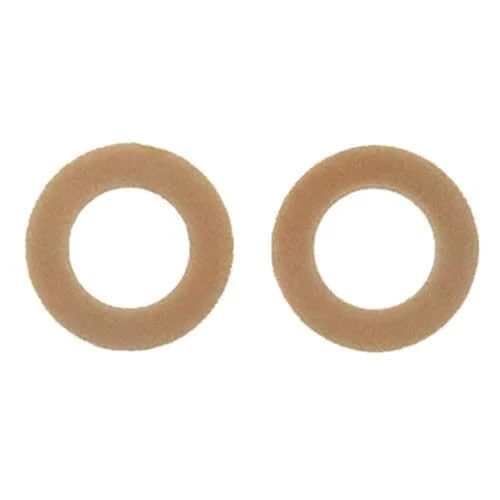

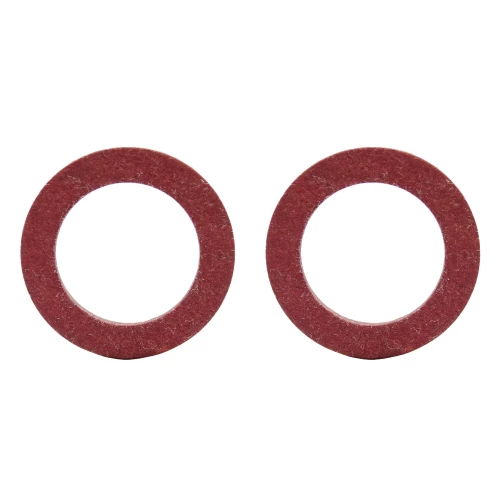

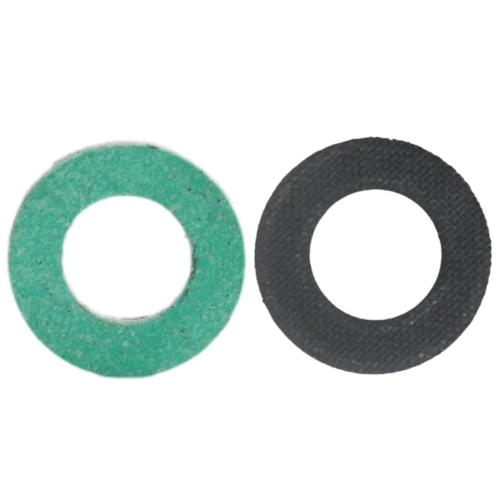

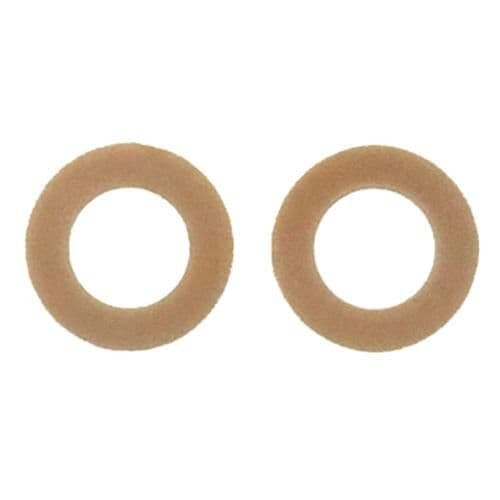

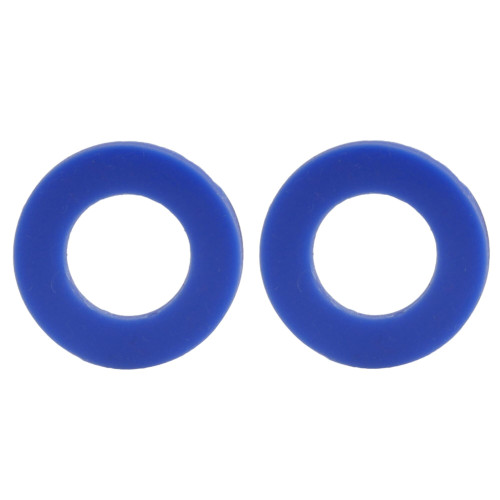

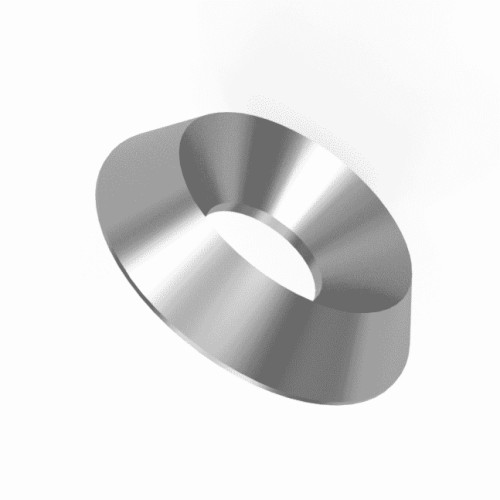

Washers

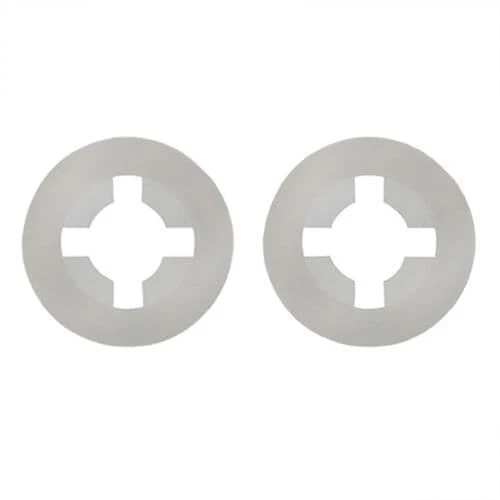

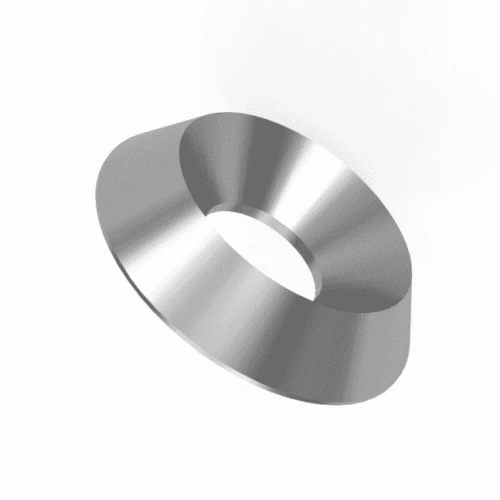

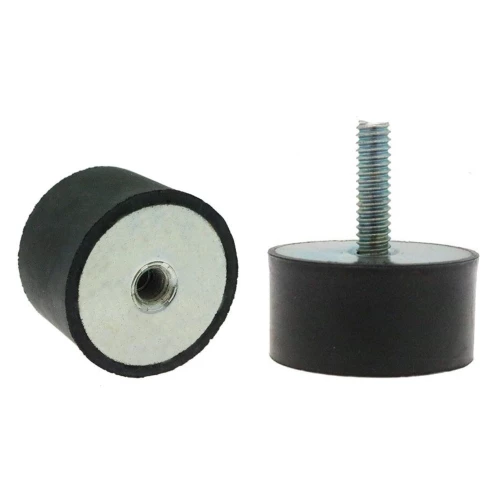

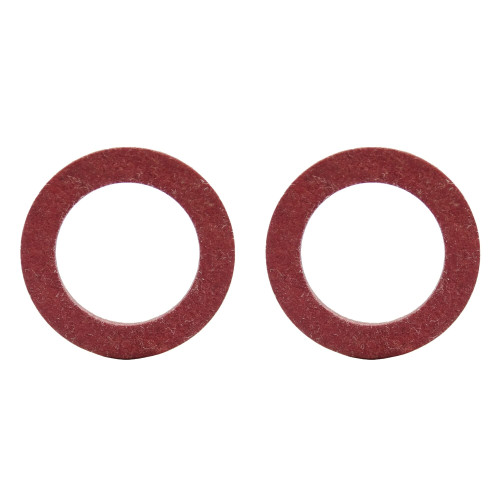

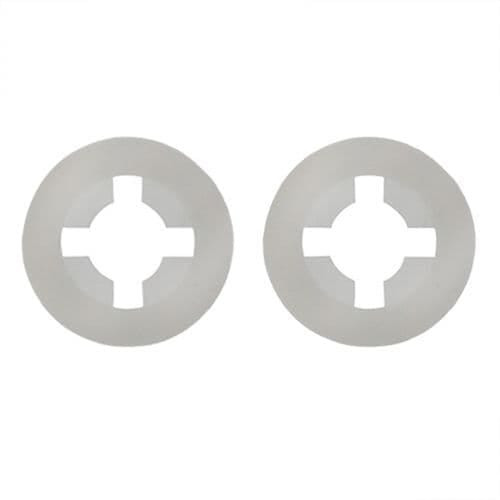

Our selection of Washers For Bolts & Fixings are manufactured using a range of high quality materials. These include Stainless Steel, Nylon 6/6, HDPE, TPR, Peek, Polypropylene, Silicone, PTFE, EPDM, Fibre and FKM. Renowned for their durability and ease of use, our Sealing Washers come in a number of styles to suit. Each of these products is ideal for a different purpose, such as vibration dampening or for preventing movement between a wall and a headboard.

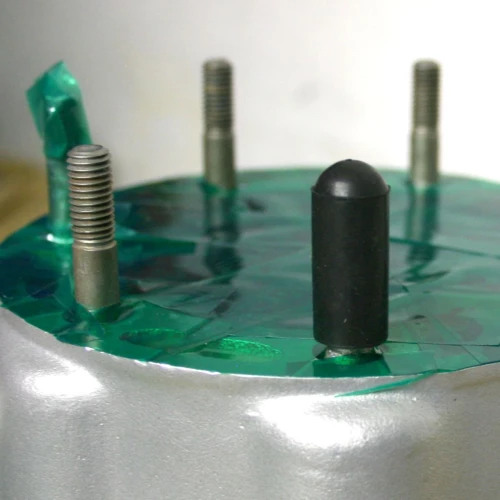

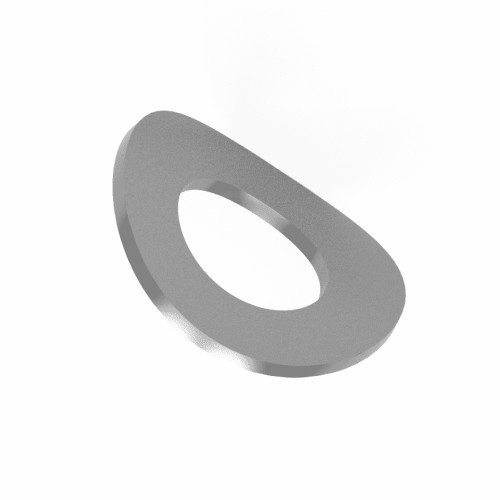

The Mechanical Washers are used to distribute the load of a threaded fastener and can also be used to increase the tension of a bolt or nut. Washers are available in a variety of shapes, sizes, and materials, and are used in a wide range of applications.

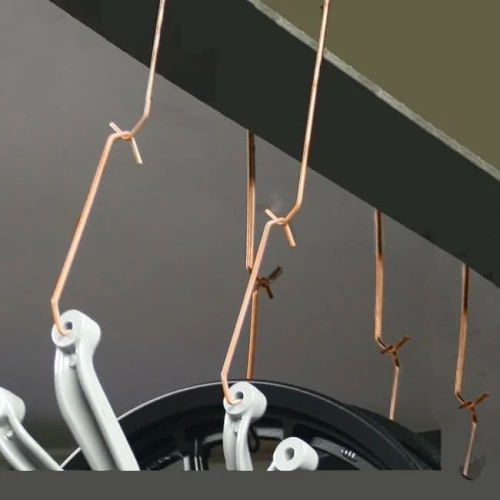

Most commonly used in conjunction with nuts, bolts and fixings, these washers pair perfectly to reduce excess movement and provide a level of compression. This can ensure a fixing stays tight over a long period of time. Washers can also regularly feature within machinery and moving parts due to their versatility, with materials such as 'Peek'. This is designed for extreme uses within Aerospace settings, where these kind of resistances are a requirement.

We stock a number of Washers For Nuts, Bolts & Fixings to suit all kinds of uses and installations, as can be seen from the vast range above. To view all available sizes, individual prices, or to request a free sample, please click through onto your required product.

We aim to provide competitive pricing across all of our Sealing Washers, with bulk pricing available.

Benefits Of Using Our Fixings Washers:

- Manufactured from premium materials including TPR, Peek & Nylon

- Range of rigorously tried and tested solutions

- Huge number of product variations

- Competitive pricing

Each Washer Has A Range Of Employments, Some Of The Most Common Include:

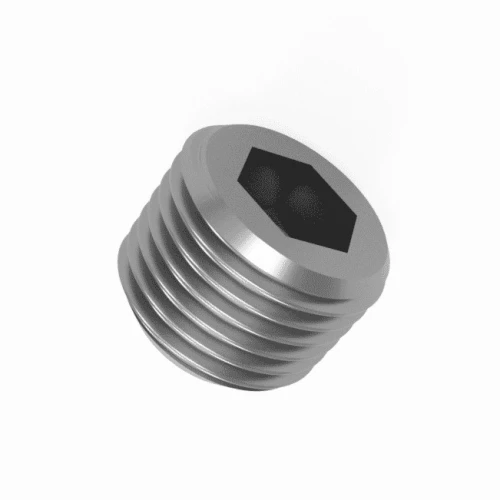

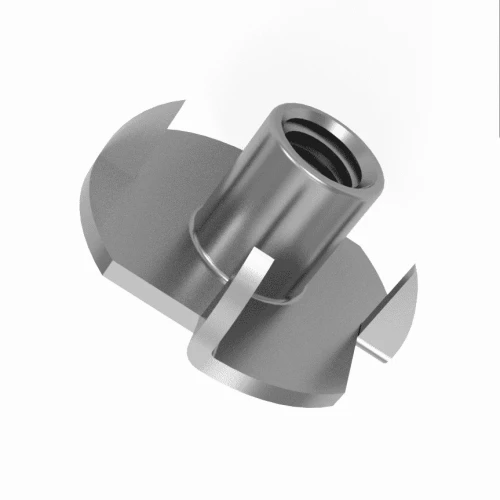

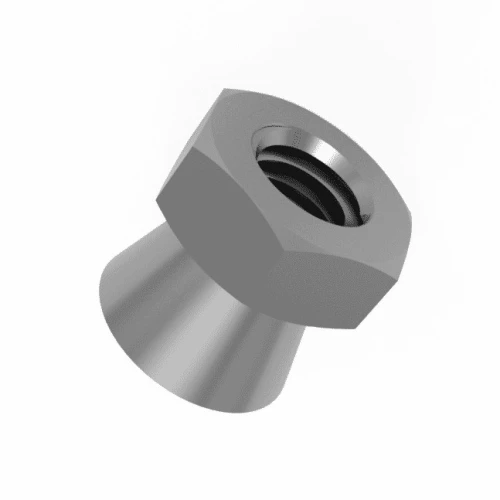

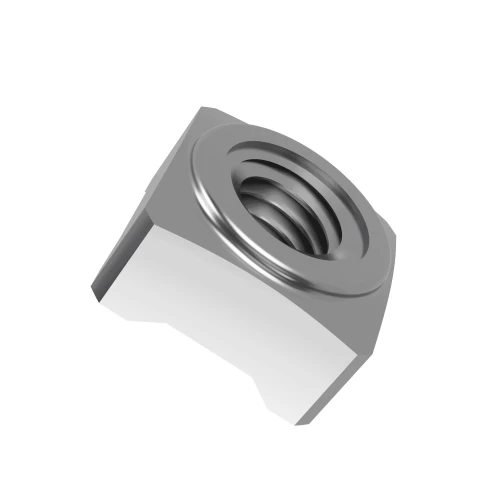

- For distributing load when fastening: Metal Washers

- For preventing a screw from becoming loose or falling out over time: Finishing Washers

- For uses where exposure to chemicals/high temperatures is likely: Peek Washers

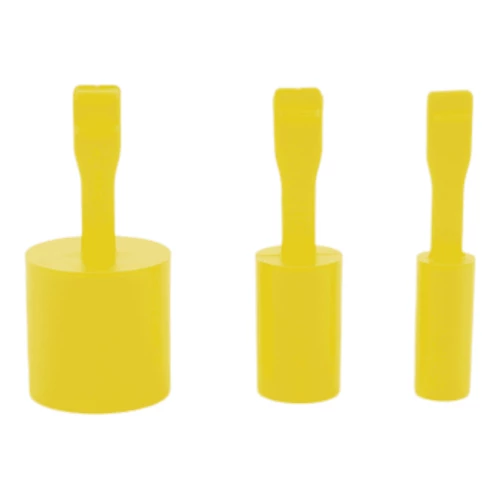

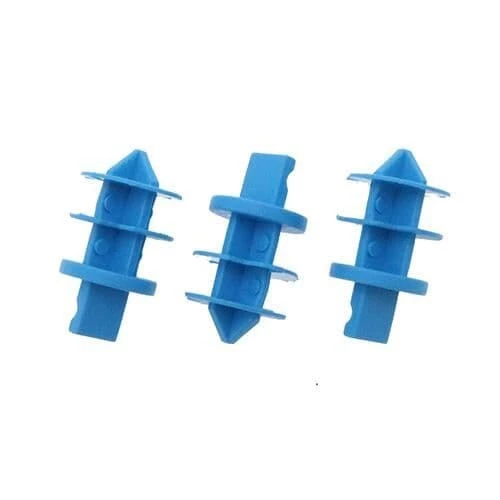

- For difficult or hard to reach area's/applications: Anti Loss Washers

- For uses requiring low friction and/or high temperature resistance: PTFE Washers

- For plumbing and water systems: WRAS Washers

- For applications requiring resistance to oils and other chemicals: FKM Washers

- For hygienic environments: Silicone Washers

Need a custom form of Washer for a job? Speak to an expert now on 01233 713581

Frequently Asked Questions

Will stainless steel washers rust?

Stainless steel washers made from standard A2 stainless steel are resistant to rust and corrosion due to the chromium that they contain. This forms a protective layer on the surface of the washer and is effective at protecting it from the oxidising effects of air and water. However, if this chromium layer is damaged by scratches or strong chemicals then the washer can still slowly rust. Additionally, salt water is still corrosive enough to damage A2 stainless steel over time. For this reason, if the washer is to be used in a marine environment, you should opt for A4 stainless steel. This contains higher levels of chromium and will be better suited to contact with sea water.

Where can I buy metal washers?

You can buy them from us! We are proud to stock a huge range of stainless steel washers. We stock many different styles, including flat washers, spring washers, curved washers, serrated washers, finishing washers and tab washers. We sell all common DIN standards, across popular thread sizes and in both A2 and A4 stainless steel grades.

What are metal washers used for?

Metal washers are generally used for distributing the load of a threaded fasteners, such as screws, bolts or nuts. They can also help to prevent them from becoming loosened and reduce corrosion. In some applications they might be used as spacers, springs, shims or locking devices.

What are the advantages of using stainless steel washers?

The advantage of using stainless steel for a washer is the resulting strength and durability of the product. They are able to withstand high pressures and temperatures over long periods of time without breaking. This makes them well suited for use in heavy machinery or in punishing industrial environments. Their resistance to rust and corrosion adds to the long lifespan of the product. They are also simple to maintain, and their shiny and smooth appearance adds a nice finishing aesthetic to an application. There is also a huge number of sizes, shapes, styles and grades of washer available to suit a specific requirement or application.

Are there any specific maintenance requirements for stainless steel washers?

Maintenance for washers is generally minimal, however, doing so will increase the longevity and lifespan of the part. The best practice is to clean them periodically using a soft cloth and a gentle detergent. Be sure to avoid using scouring pads and strong detergents as these can damage the protective layer of the stainless steel. They should then be rinsed well with water and dried thoroughly with a clean towel.

Are washers sold individually or in packs?

All of our washers are sold individually. This is across all available washer materials from standard nylon, rubber and peek washers, to silicone washers, PTFE washers and plastic washers. This also includes our specialist EPDM and fibre WRAS washers, and stainless steel washers.

Do washers come with specific certifications or standards?

Some washers are designed for specific industries and applications and may come with a certification or be manufactured to a certain standard. One example is our range of WRAS washers, these are made from EPDM or Fibre material and have passed the regulations and standards for use in plumbing and water supply applications. Under UK law, this certification is necessary for any water fittings that come into contact with drinking water. A second example can be found in the food industry, where it is necessary to ensure that strictly only food safe materials come into contact with any foods. Therefore, washers that have been certified as food safe are necessary for use in food processing equipment and machinery.

Are there different types of washers available for specific applications?

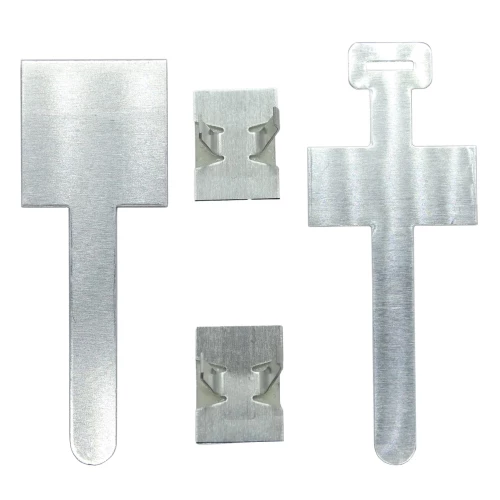

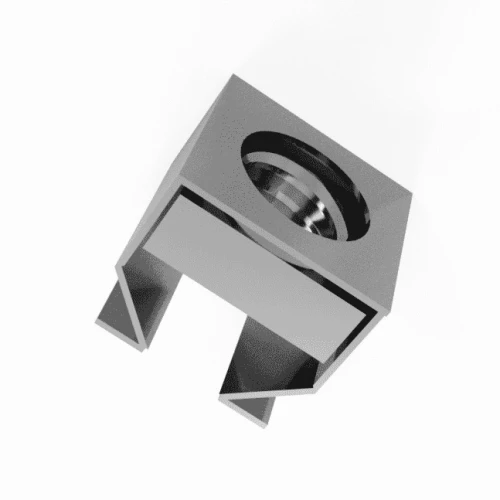

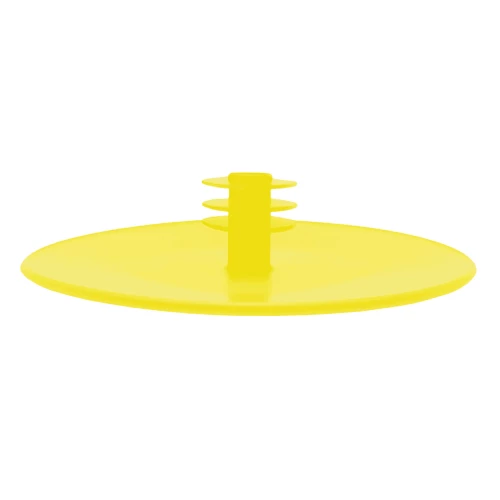

In addition to the standard flat washer, which is available in many different materials and sizes, there are washers that have been designed for specific applications. One example of this is saddle washers, these washers have a uniquely curved shape that allows them to join round tube to various surfaces. They are also effective in applications where the object they are seating needs to rotate. Additionally, finishing washers are used to give a clean aesthetic to applications that utilise exposed screw heads. You might often find this in furniture such as cabinets. The finishing washers are used to cover the screw head, and usually use a material and colour that blends in with the furniture. Finishing washers will also protect the surface of the furniture or object from any scratching that could occur as the fixing screw is tightened.

Can washers be customised or ordered in bulk?

We are able to supply washers in bulk quantities. We have provided bulk pricing on our washer product pages to show the pricing discounts that are available for purchasing varying numbers of units. If you are looking for a bulk quantity that is far in excess of the final bulk pricing bracket, then please contact us, as we may be able to offer further discounts on wholesale and commercial purchases of washers. If you require a large batch of customised washers, or washers created to a specification that you don't see listed on the site then please contact us. In most cases we will be able to supply additional varieties of washers that are not listed on our website, within a short lead time.

What are washers also known as?

Washers are a very straightforward component and it generally isn't difficult to name them effectively. Most people will use the material that the washer is made from as the defining characteristic when they name it. For example, customers may ask for rubber washers, nylon washers, plastic washers or metal washers. This is usually a good starting point as it helps us to narrow down a suitable selection of products. It can also be useful to use the style of the washer, e.g. a penny washer, a spring washer or a flat washer. Tradesmen might describe washers in terms of their application, for example a tap rubber washer, or a shower head rubber washer. This is another useful way to distinguish between different types of the washers. It can also be useful to search for washers by thread size e.g. m10 washer or m4 washer. If a customer is searching for an m5 washer then it is clear that the product they are looking for must be sized to fit an m5 thread. We've included a handy filter on our website that allows you to only display washers of a certain size.

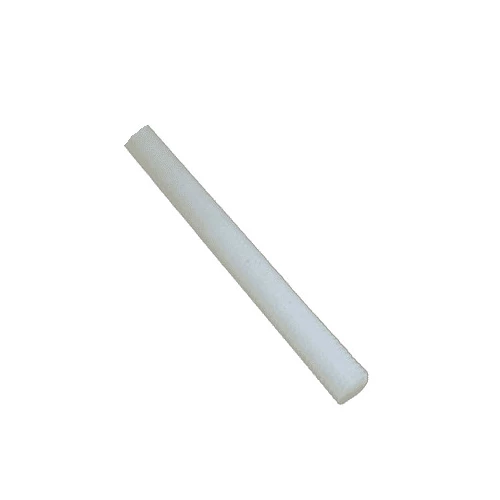

Do you sell white rubber washers?

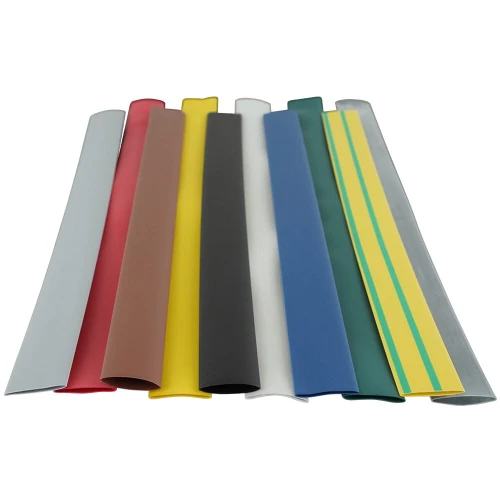

We can supply white rubber washers as part of our standard product catalogue. Our standard nylon washers are available in a natural finish, which is a milky off-white colour. It is also possible to request a pure white coloured variation of rubber washers, just reach out to our team for more information.

Can you supply big rubber washers?

If you're looking for big rubber washers, then you've come to the right place. There is no limit to the size of rubber washers that we can provide. At the same time, we can adapt the dimensions to exactly fit your desired application. For big rubber washer enquiries simply reach out to our team and let them know your requirements. They will then be able to calculate the estimated costs and lead times and eliminate the hassle of searching around for uncommon washer sizings.

Which is better rubber or silicone washers?

The answer to which is a better choice out of rubber or silicone washers will depend on the application that you will use the washers for. Generally speaking, rubber washers are a great allround washer that will perform adequately in most general applications. Silicone is a more specialised material that offers a few key advantages over standard rubber. Silicone washers stand out for their UV resistance and non-toxic nature. They won't react with substances and leach chemicals into an environment and they also have some non-stick properties. This makes them a popular choice for food production factories and pharmaceutical plants where drugs or medical products are being produced. If you're unsure which material is most suitable for your industry or application, then our team is on hand to offer advice during UK office hours.

How fast can I get my order?

Need your parts tomorrow? Our rapid same day dispatch has got you covered! Simply place your order before 4pm Mon-Thurs or 2pm Friday and select our Next Day Delivery service in the shopping cart. We also offer Guaranteed AM delivery when required, in addition to a Saturday delivery option.

If you don't mind waiting, we have a Free delivery method for orders over £30, and an economic £4.85 2nd Class delivery for orders between £10-£30.

Can I get a Free Sample?

Free Samples can be requested through our product pages, displayed in the sizing table beside the product you require. Please note you can always give us a call on 01233 713 581 or contact us on Live Chat to discuss samples.

Do I need to Sign Up for an account?

You do not need to sign up to place an order, but it is recommended if you'd like to gain loyalty points, giving discount off future orders. To learn more about loyalty points, please view our rewards scheme page.

I am not sure what parts I need?

If you're unsure which part you need then please do not hesitate to give one of our friendly Sales Team a call on 01233 713 581 and they can assist you. Alternatively, we're active on Live Chat during office hours. You can open this using the button in the bottom right corner of the website. Alternatively, you can write to us using our contact form.

Do you offer Returns on Products?

We offer a return period on all of our products to give you peace of mind, to view our policies and learn more about this process should it be required, please see our returns policy page.

Can you supply different colours of this product?

In most cases we have the facilities to offer you different colours of a product, specific to your requirements. Minimum order quantities may apply depending on the manufacturing technique in question, but please get in touch with any queries you may have.

Is there a minimum order value?

Please note that there is a minimum order value of £10 through our website (inclusive of VAT).

If you're new to our website you may want to check out our frequently asked questions section for answers to common customer queries.

What do these abbrievations mean?

While browsing the website you may come across abbreviations used for material names that you are unfamiliar with. You can find an explanation for these in our material abbreviations guide.

Vital Parts is rated 4.79 stars by Reviews.co.uk based on 1209 merchant reviews