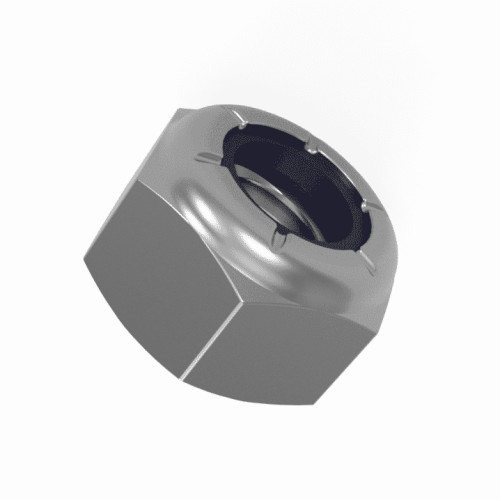

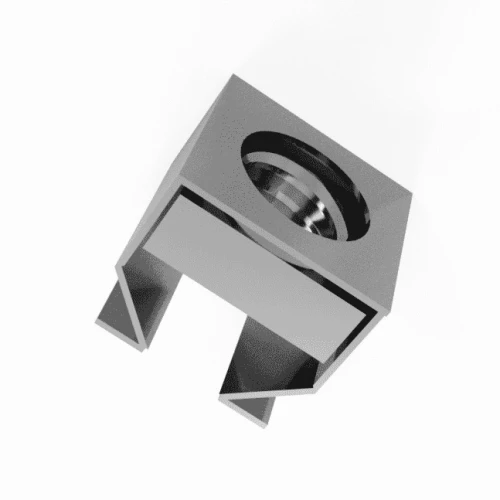

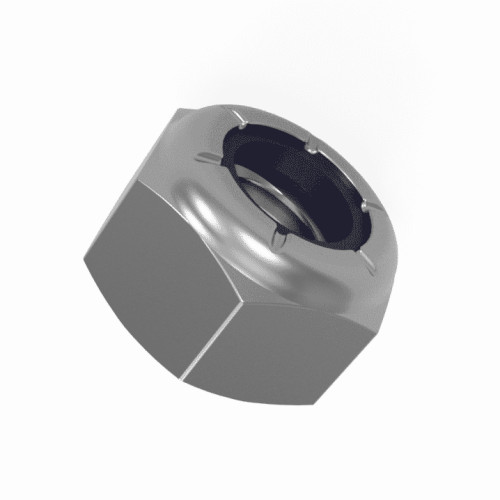

Locking Hex Nuts

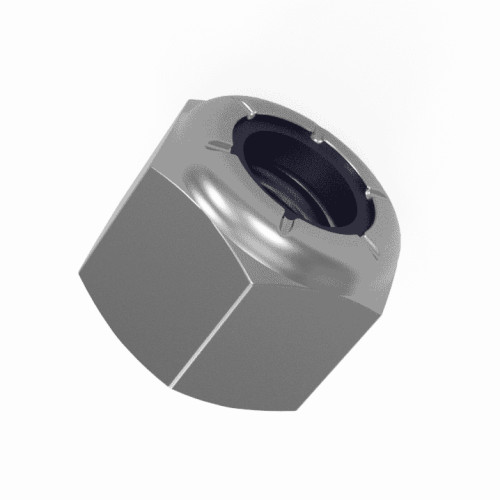

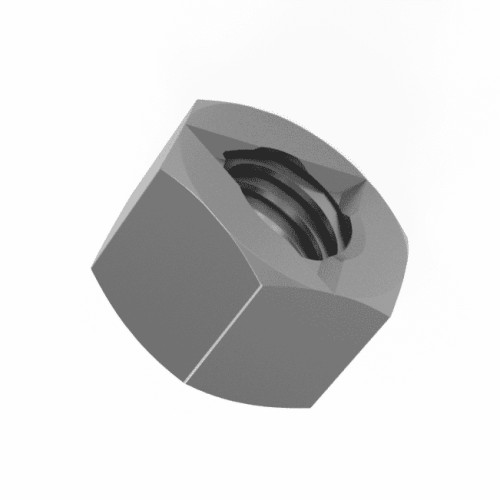

Locking nuts might also be known as nyloc nuts or simply lock nuts are made with a nylon lining, acting as a thread locking compound. Nyloc nuts are designed to resist loosening under both vibration and torque. The nylon deforms upon a thread tightening against it creating a locking mechanism which is commonly used in Machinery, vehicles, bicycles and other moving parts due to the interference it creates. DIN 980V Nuts as all metal locking nuts, which don't include a nylon insert. Instead the metal is deformed as the thread is not fully formed.

Locking nuts are ideal for use in applications where one expects a nut to be subjected to vibration or shock loads. They are commonly used in the automotive industry, construction, machinery, and other applications where maintaining a secure connection is critical.

Some benefits of using locking nuts:

- Resist loosening from vibration and torque

- Reusable

- Easy to install and remove

- Wide range of sizes available

Considerations

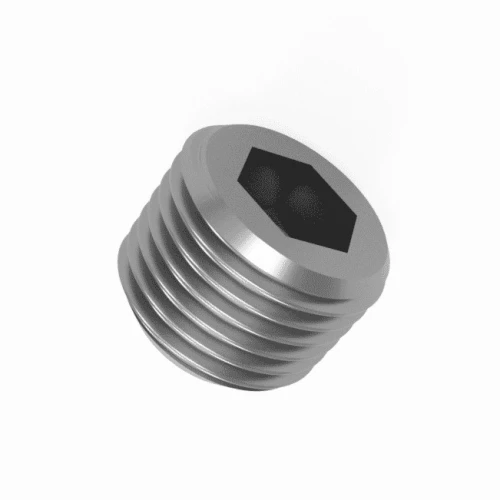

When choosing locking nuts, it is important to consider the size, material, and finish of the nut. The size of the nut should be compatible with the bolt threads. The material of the nut should be appropriate for the application. For example, stainless steel locking hex nuts are a good choice for applications where corrosion resistance is important. The drive of the nut should also be considered. Though different styles of locking nuts are available, these hex locking nuts are tightened using a hex key / allen key.

Nyloc Hex Nuts are reusable but the effectiveness of the locking mechanism over time will detract after repeated use however they are an easy to use, straightforward, cost effective product that are highly popular.

Frequently Asked Questions

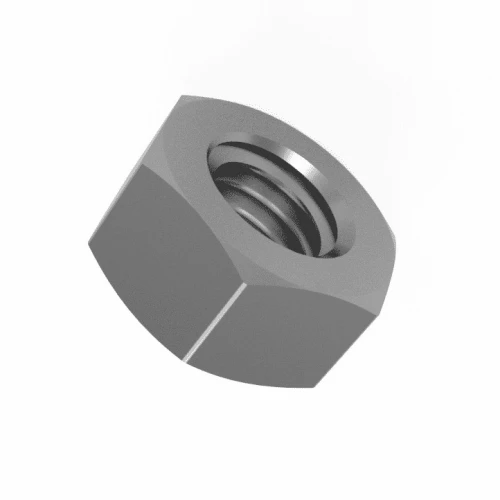

What is the difference between hex nuts and locking hex nuts?

Both standard hex nuts and locking hex nuts share the same six sided, hexagonal shape. This is the common, go-to shape for a nut, thanks to the increased grip that this provides to a wrench or spanner, when used for tightening or loosening. The crucial difference with locking nuts is that they contain a nylon insert inside of the nut. This insert creates resistance against the threads that meet when the nut is tightened onto the application's thread. The increased resistance adds increased friction to the nut's application and this helps to keep the nut in place. For this reason, a locking nut might also be described as a nylon insert lock nut. Locking nuts have been designed to prevent self-loosening or the unintentional loosening of the nut over time. This may occur in applications where the nut and joining thread is exposed to vibration or movement. In these scenarios, for critical or high-stress applications it is therefore recommended to use locking nuts over standard hex nuts.

What are locking hex nuts also known as?

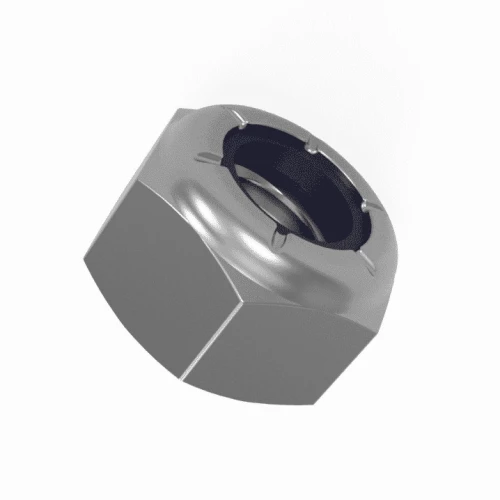

There are a few different ways to refer to locking nuts, most of them stem from the nylon insert that most common types of locking nuts utilise. Nylon locking nuts and nylon insert lock nuts are two common terms. However, the most popular name for locking hex nuts is nyloc nuts (also sometimes spelt nylock nuts). There are also all metal versions of locking hex nuts and instead of using an inserted nylon thread, they will use a metal inserted thread. These are usually just called metal locking nuts.

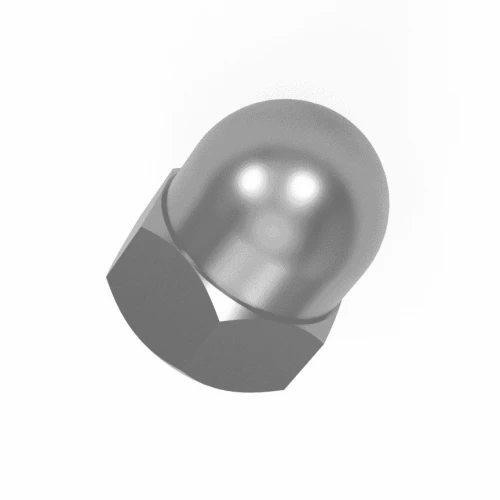

What types of locking hex nuts do you sell?

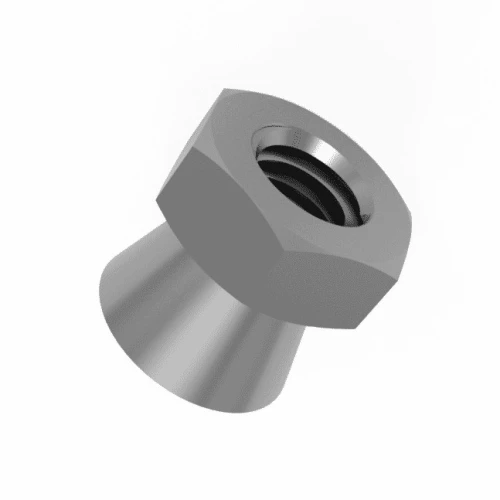

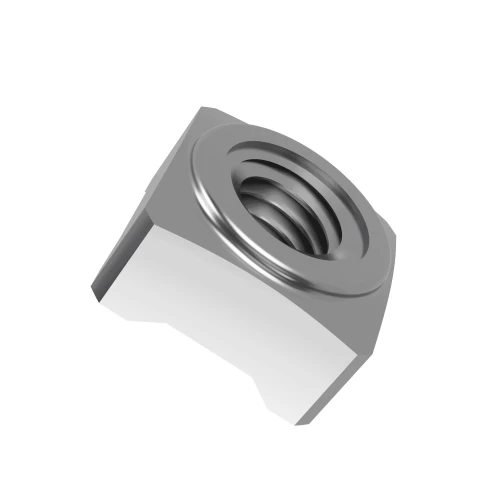

We supply the three most common styles of locking nuts, these are: standard lock hex nuts, high lock hex nuts and all metal locking hex nuts. High lock hex nuts are like the standard locking hex nuts. They use a nylon insert to create resistance and have an increased height. The term "high" refers to the fact they will sit higher on a thread than a standard locking hex nut. The all metal locking nuts use a triangular indent on the top threads of the nut, instead of a nylon insert. Hence, our all metal locking hex nuts will be manufactured completely from high strength stainless steel.

What is a nyloc nut?

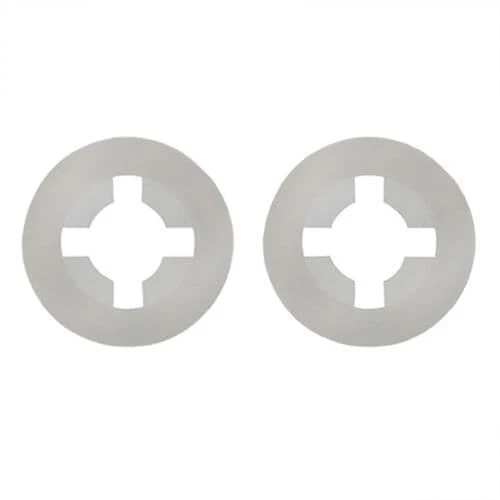

The term nyloc nut is used to describe a common type of locking nut that contains a small circular nylon ring that is inserted into the nut's thread. The nylon insert increases the friction as the nut is tightened onto a thread and helps to prevent loosening that could occur due to vibrations or shocks. The nylon insert is the defining part of nylock, which combines the terms nylon and lock, to describe this popular style of locking nut. The locking element of a nyloc nut comes from the prevailing torque that is applied to the nut by the nylon insert as it is tightened against the thread of an application.

What are nyloc hex nut used for?

Nyloc nuts, nyloc hex nuts or nylon locking nuts are often applied in vibration prone environments where constant or strong vibrations may cause standard hex nuts to loosen over time. Nylock hex nuts are also important for critical or high load applications where the integrity of joints must be maintained. The ability of nyloc nuts to resist loosening over time is a key part of enhancing joint integrity. Their ability to secure heavy loads, even when exposed to vibrations, makes them a value component for fastening components in the automotive and aerospace industries. Similarly, they are a good choice for use in heavy industrial machinery such as conveyor systems, or in structural components and scaffolding within the construction sector.

What thread sizes of nyloc nuts do you offer?

Nyloc nuts are an important fastening component and one of the most popular types of locking hex nuts within the UK market. We are proud to offer nylock nuts in a wide range of metric thread sizes. Our extensive sizing available in our standard catalogue ensures that our customers can source the right nylon lock nuts for their application. M8 nyloc nuts are the most popular thread size purchased by our customers. This is closely followed by M6 nyloc nuts in second place and then a tie between M10 nyloc nuts and M12 nyloc nuts. We supply nylock hex nuts starting at an M3 size, all the way up to M24. If you require a size that isn't listed, like a non-metric size for example, then please contact us as we may still be able to help.

Are nyloc nuts reusable?

The main feature of nyloc nuts is to provide resistance against the self-loosening of nuts. For this reason, the nylon insert that they contain is essential to their continued efficiency. It is generally possible to reuse nylock nuts multiple times, however, this will depend on the condition of its nylon insert at the end of its first application. There are a few factors that heavily influence the reusability of nyloc nuts, mainly environmental exposure and proper installation and removal processes. Contact with extreme temperatures, chemicals or high exposure to UV light will degrade the condition of the internal nylon insert. Similarly, if nyloc nuts are overtightened during installation or excessive force is used during removal, then this will also damage the nylon insert. For critical applications it is recommended to never reuse nyloc nuts and instead use a fresh nylon locking nut on each application, as this will ensure the maximum performance of the part.

What does DIN 985 mean?

DIN 985 is a German standard specification for prevailing torque type hexagon nuts with non-metallic inserts, commonly known as thin nyloc nuts or Type T nylon lock nuts. These nuts feature a nylon insert that deforms over the mating threads, creating a prevailing torque mechanism that increases friction and prevents unintentional loosening due to vibrations or external forces. The standard was established by the German Institute for Standardisation and is now recognized internationally.

Key Features of DIN 985:

• Thin Profile Design: Lower height compared to DIN 982 nuts, ideal for space-constrained applications

• Nylon Insert Technology: Creates friction-based locking mechanism

• Vibration Resistance: Prevents loosening under dynamic loads

• Reusable: Can be used multiple times while maintaining effectiveness

What's the difference between DIN 985 and DIN 982?

The primary difference between DIN 985 and DIN 982 nyloc nuts lies in their height profiles:

DIN 985 (Type T - Thin):

• Standard thin profile variant designed for applications where space is at a premium

• Lower overall height for compact assemblies

• Ideal for precision engineering and lightweight applications

DIN 982 (Type P - Thick):

• Higher profile variant with more available thread engagement

• Distinguished by their greater overall height for added security

• Better for applications requiring maximum thread engagement

Both standards use the same nylon insert technology and provide excellent vibration resistance, with the choice typically dependent on space constraints and thread engagement requirements.

What are the main applications for DIN 985 nuts?

DIN 985 nyloc nuts are widely used across multiple industries due to their superior vibration resistance:

Automotive Industry:

• Engine, transmission, and suspension systems where vibrations are generated during operation

• Components that must remain secure under severe conditions

Industrial Machinery:

• Heavy machinery where vibrations are inherent, providing dependable solutions for securing critical components

• Manufacturing equipment and production lines

• Mining machinery, agricultural machinery, and textile machinery

Construction & Infrastructure:

• Construction projects involving structures susceptible to vibrations, ensuring longevity of fastened joints

• Steel framework connections

• Structural assemblies requiring long-term reliability

Aerospace & Defense:

• Aerospace applications where reliability and stability are paramount

• Critical systems requiring fail-safe fastening

Precision Engineering:

• Applications where space and weight constraints are a concern, such as precision engineering and lightweight assemblies

How fast can I get my order?

Need your parts tomorrow? Our rapid same day dispatch has got you covered! Simply place your order before 4pm Mon-Thurs or 2pm Friday and select our Next Day Delivery service in the shopping cart. We also offer Guaranteed AM delivery when required, in addition to a Saturday delivery option.

If you don't mind waiting, we have a Free delivery method for orders over £30, and an economic £4.85 2nd Class delivery for orders between £10-£30.

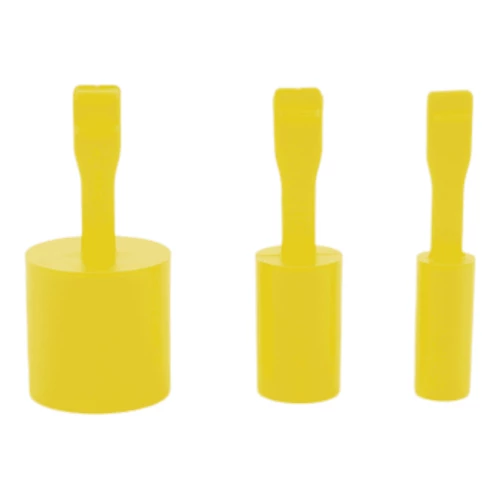

Can I get a Free Sample?

Free Samples can be requested through our product pages, displayed in the sizing table beside the product you require. Please note you can always give us a call on 01233 713 581 or contact us on Live Chat to discuss samples.

Do I need to Sign Up for an account?

You do not need to sign up to place an order, but it is recommended if you'd like to gain loyalty points, giving discount off future orders. To learn more about loyalty points, please view our rewards scheme page.

I am not sure what parts I need?

If you're unsure which part you need then please do not hesitate to give one of our friendly Sales Team a call on 01233 713 581 and they can assist you. Alternatively, we're active on Live Chat during office hours. You can open this using the button in the bottom right corner of the website. Alternatively, you can write to us using our contact form.

Do you offer Returns on Products?

We offer a return period on all of our products to give you peace of mind, to view our policies and learn more about this process should it be required, please see our returns policy page.

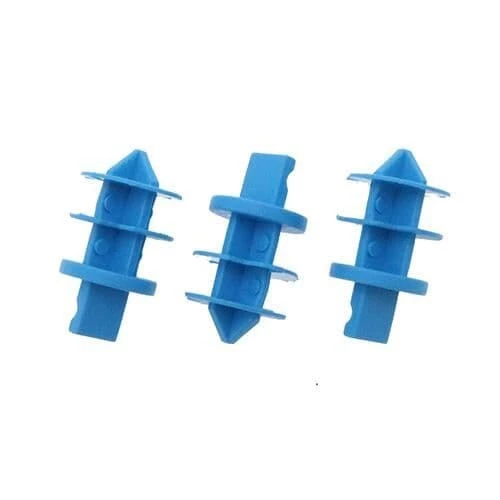

Can you supply different colours of this product?

In most cases we have the facilities to offer you different colours of a product, specific to your requirements. Minimum order quantities may apply depending on the manufacturing technique in question, but please get in touch with any queries you may have.

Is there a minimum order value?

Please note that there is a minimum order value of £10 through our website (inclusive of VAT).

If you're new to our website you may want to check out our frequently asked questions section for answers to common customer queries.

What do these abbrievations mean?

While browsing the website you may come across abbreviations used for material names that you are unfamiliar with. You can find an explanation for these in our material abbreviations guide.

Vital Parts is rated 4.79 stars by Reviews.co.uk based on 1209 merchant reviews