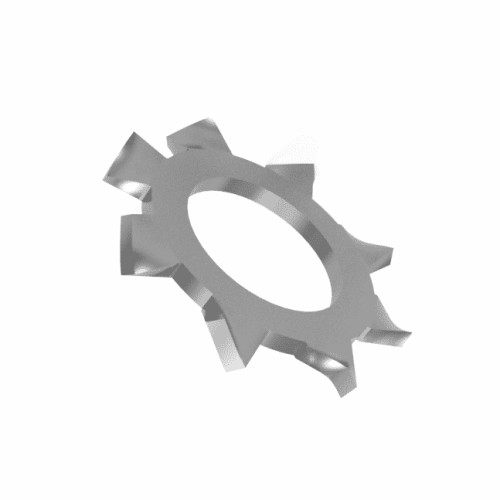

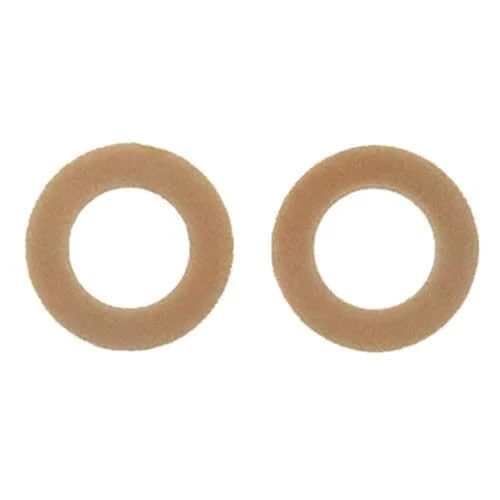

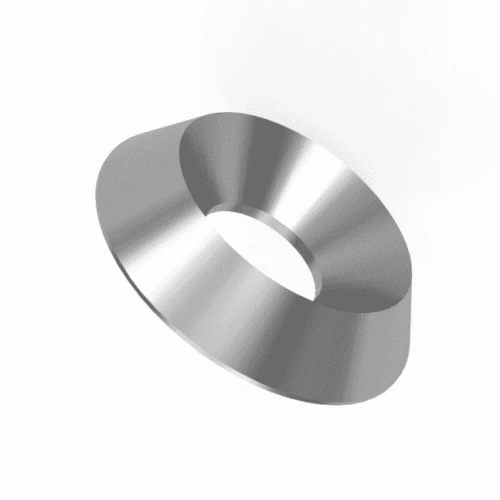

Stainless Steel Serrated Washers

Stainless steel serrated washers are a type of washer that has a series of teeth or ridges on its surface. These teeth or ridges are designed to provide a more secure connection when used with a fastener. They are available in both external and internal toothed varieties. External toothed serrated washers are designed to be used with a flat head fastener and provide a secure connection when tightened. Internal toothed serrated washers are designed to be used with a pan head fastener and provide a secure connection when tightened. Both varieties are typically made from stainless steel and are available in a variety of sizes and thicknesses.

These are available in A2 stainless steel in sizes from M2 to M30.

Categories

-

Plugs & Stoppers

-

Tapered Rubber Plugs

Tapered Rubber Plugs -

Silicone Ribbed Plugs

Silicone Ribbed Plugs -

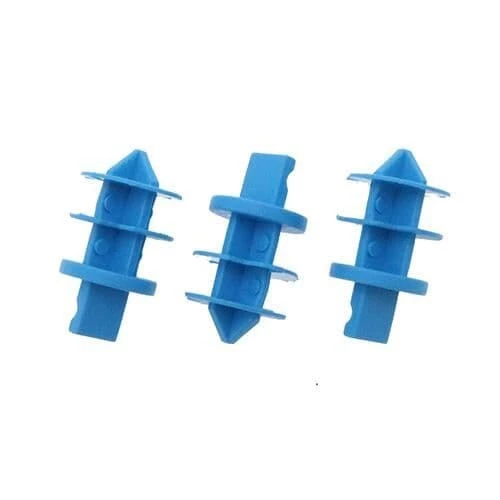

Silicone Tapered Plugs

Silicone Tapered Plugs -

Silicone Plugs With Handle

Silicone Plugs With Handle -

Silicone Step Plugs

Silicone Step Plugs -

Silicone Pull Plugs

Silicone Pull Plugs -

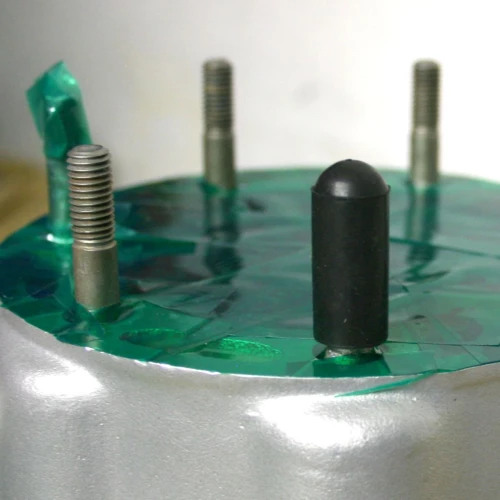

Silicone Thread Masking Plugs

Silicone Thread Masking Plugs -

Threaded Plugs

Threaded Plugs -

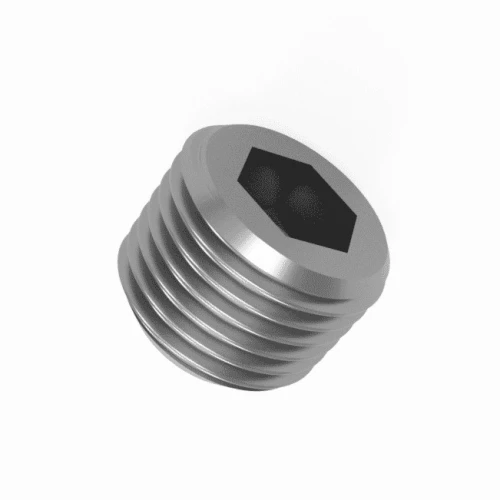

Threaded Sealing Plugs

Threaded Sealing Plugs -

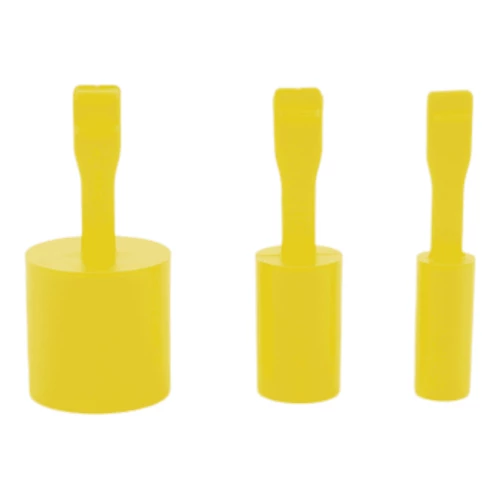

Cylindrical Pull Tab Plugs

Cylindrical Pull Tab Plugs -

Finned Pull Tab Plugs

Finned Pull Tab Plugs -

Fir Tree Plugs

Fir Tree Plugs -

Reversible Tapered Plugs

Reversible Tapered Plugs -

Round Tube Plugs

Round Tube Plugs -

Snap Fit Hole Plugs

Snap Fit Hole Plugs -

Stainless Steel Socket Pipe Plugs DIN 906

Stainless Steel Socket Pipe Plugs DIN 906 -

Door Stoppers

Door Stoppers -

Door Wedge

Door Wedge -

Finned Hole Plugs

Finned Hole Plugs -

Plastic End Plugs

Plastic End Plugs -

Ribbed Pipe End Plugs

Ribbed Pipe End Plugs -

Blanking Plugs

Blanking Plugs -

Ventilation Plugs

Ventilation Plugs -

Snap Fit Bushes

Snap Fit Bushes -

Liquid Tight Plugs

Liquid Tight Plugs -

Barrel Plugs

Barrel Plugs -

Washer Masking Plugs

Washer Masking Plugs -

Measurement Guide

Measurement Guide -

Silicone Flange Plugs

Silicone Flange Plugs -

Silicone Double Flange Plugs

Silicone Double Flange Plugs

-

-

Furniture & Chair Feet

-

Sofa Feet

Sofa Feet -

Screw In Furniture Feet

Screw In Furniture Feet -

Anti-Sink Feet

Anti-Sink Feet -

Round Ferrules

Round Ferrules -

Square Ferrules

Square Ferrules -

Walking Stick Ferrules

Walking Stick Ferrules -

Crutch Feet

Crutch Feet -

Push In Feet

Push In Feet -

Nail On Feet & Glides

Nail On Feet & Glides -

Office Chair and Furniture Castors

Office Chair and Furniture Castors -

Insert Glides

Insert Glides -

Saddle Feet

Saddle Feet -

Furniture & Chair Glides

Furniture & Chair Glides -

Stick On Feet & Pads

Stick On Feet & Pads -

School Chair & Furniture Feet

School Chair & Furniture Feet -

Fitting Guide

Fitting Guide

-

-

Adjustable Feet

-

Balance Feet

Balance Feet -

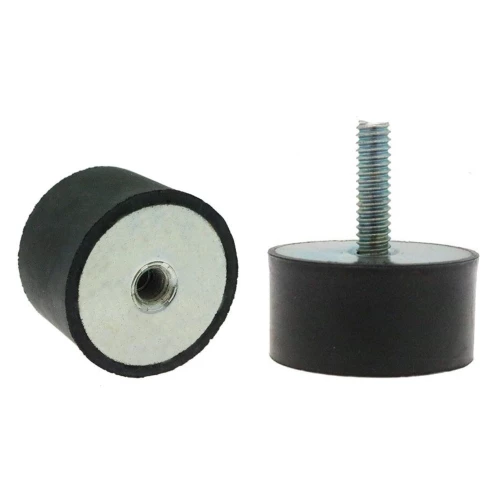

Anti-Vibration Levelling Feet

Anti-Vibration Levelling Feet -

Economic Adjustable Feet

Economic Adjustable Feet -

Slotted Head Adjustable Feet

Slotted Head Adjustable Feet -

Rubber Adjustable Feet

Rubber Adjustable Feet -

Stainless Steel Adjustable Feet

Stainless Steel Adjustable Feet -

Ready To Install Sets

Ready To Install Sets -

Weight Rated Articulated Feet

Weight Rated Articulated Feet -

Allen Key Adjustable Feet

Allen Key Adjustable Feet -

General Adjustable Feet

General Adjustable Feet -

Heavy Duty Tilting Feet

Heavy Duty Tilting Feet -

Tilting Adjustable Feet

Tilting Adjustable Feet -

Pozi Base Adjustable Feet

Pozi Base Adjustable Feet -

Polyamide Adjustable Feet

Polyamide Adjustable Feet -

One Piece Adjustable Feet

One Piece Adjustable Feet -

Metal Adjustable Feet

Metal Adjustable Feet -

Machinery Mounting Feet

Machinery Mounting Feet -

Threaded Fittings & Fixings

Threaded Fittings & Fixings -

Fitting Guide

Fitting Guide -

Low Profile Adjustable Feet

Low Profile Adjustable Feet -

Hexagon Base Feet

Hexagon Base Feet

-

-

Cable Management

-

Aluminium Cable Clips

Aluminium Cable Clips -

Rubber Grommets

Rubber Grommets -

Braided Cable Sleeving

Braided Cable Sleeving -

Cable Glands

Cable Glands -

PVC Cable Sleeving

PVC Cable Sleeving -

Spiral Cable Wrap

Spiral Cable Wrap -

Strain Relief

Strain Relief -

Nylon P Clips

Nylon P Clips -

Nylon P Clamps

Nylon P Clamps -

Cable Ties

Cable Ties -

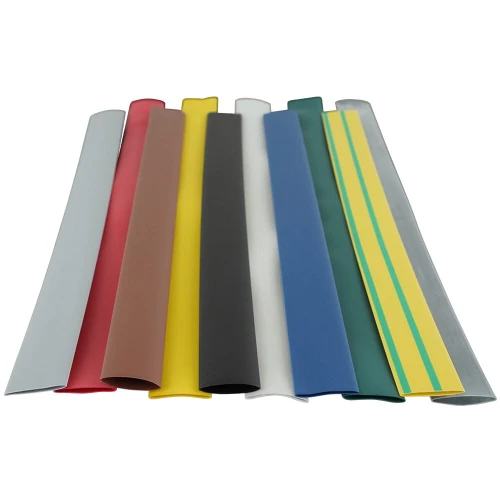

Heat Shrink Sleeves

Heat Shrink Sleeves -

Adhesive Lined Heatshrink

Adhesive Lined Heatshrink -

Cable Tie Mounts

Cable Tie Mounts -

Desk Cable Tidies

Desk Cable Tidies -

Velcro Cable Management

Velcro Cable Management -

Multi Cable Clips

Multi Cable Clips -

Plastic Grommet Strips

Plastic Grommet Strips -

Heat Shrink Caps

Heat Shrink Caps -

Rubber Grommet Strips

Rubber Grommet Strips

-

-

Bolts and Screws

-

Cheese Head Slotted Screws DIN 84

Cheese Head Slotted Screws DIN 84 -

Pipe Plugs

Pipe Plugs -

Hex Head Screws and Bolts

Hex Head Screws and Bolts -

Cap Screws

Cap Screws -

Button Screws

Button Screws -

Countersunk Screws

Countersunk Screws -

Pan Head Machine Screws

Pan Head Machine Screws -

Security Fasteners

Security Fasteners -

Screws for Plastic

Screws for Plastic -

Knurled Fasteners

Knurled Fasteners -

Grub Screws

Grub Screws -

Threaded Rod (All Thread)

Threaded Rod (All Thread) -

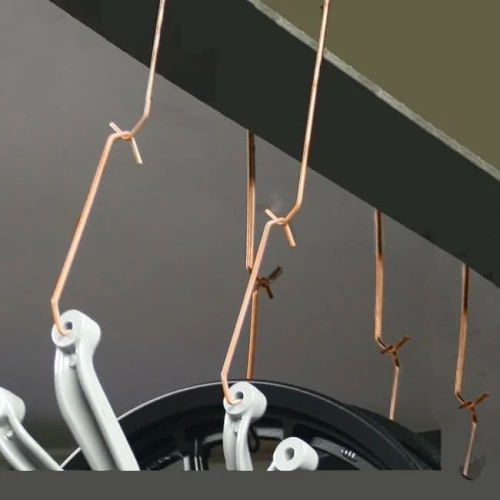

Weld Studs

Weld Studs -

Small Bolts

Small Bolts -

Stainless Steel Bolts By Metric Thread Size

Stainless Steel Bolts By Metric Thread Size -

Large Bolts

Large Bolts

-

-

Washers

-

Bonded Sealing Washers

Bonded Sealing Washers -

Standard Nylon Washers

Standard Nylon Washers -

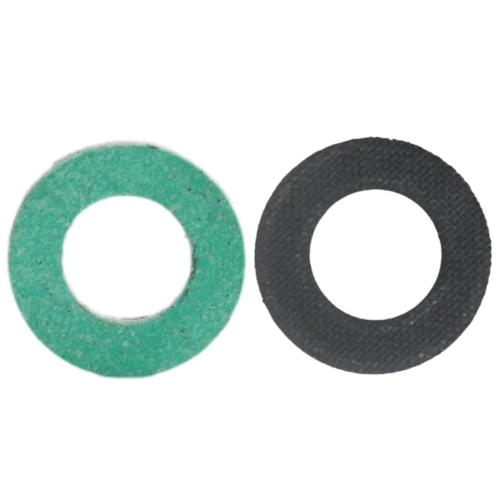

Rubber Washers

Rubber Washers -

Peek Washers

Peek Washers -

Silicone Washers

Silicone Washers -

Red Fibre Washers

Red Fibre Washers -

PTFE Washers

PTFE Washers -

FKM Washers

FKM Washers -

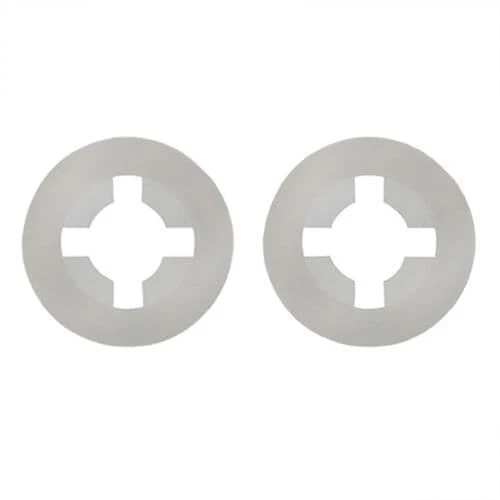

Anti-Loss Washers

Anti-Loss Washers -

Finishing Washers

Finishing Washers -

Headboard Washers

Headboard Washers -

Saddle Washers

Saddle Washers -

Stainless Steel Flat Washers

Stainless Steel Flat Washers -

Stainless Steel Spring Washers

Stainless Steel Spring Washers -

Stainless Steel Curved Washers

Stainless Steel Curved Washers -

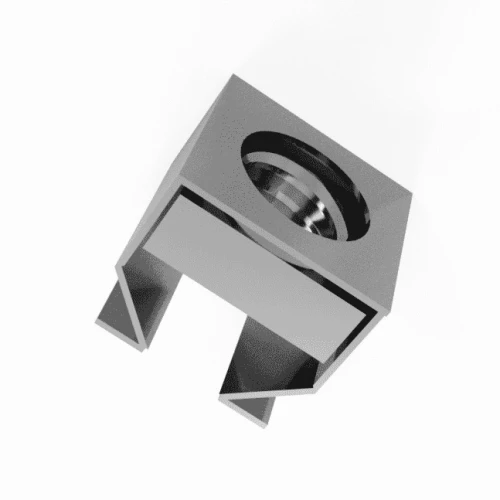

Stainless Steel Serrated Washers

Stainless Steel Serrated Washers -

Stainless Steel Finishing Washers

Stainless Steel Finishing Washers -

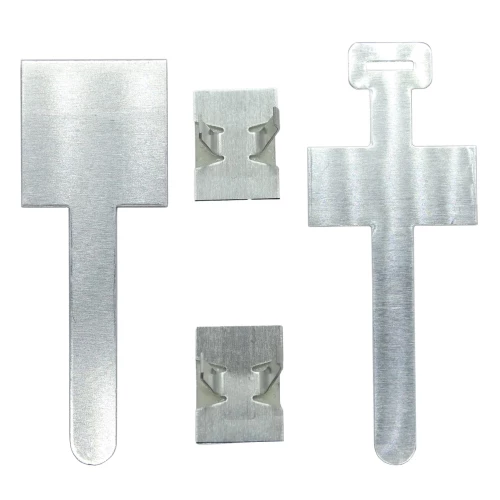

Stainless Steel Tab Washers

Stainless Steel Tab Washers -

WRAS Washers

WRAS Washers

-

-

Plastic & Nylon Fasteners

-

Industrial Hardware

-

General Handwheels

General Handwheels -

Door Bolts

Door Bolts -

Hinges

Hinges -

Latches

Latches -

Camlocks

Camlocks -

Index Plungers

Index Plungers -

Detent Pins

Detent Pins -

Furniture Fixings

Furniture Fixings -

Clamping Handles

Clamping Handles -

Bridge Handles

Bridge Handles -

Pull Handles

Pull Handles -

Ball Knobs

Ball Knobs -

Threaded Handwheels

Threaded Handwheels -

Wing Screws & Knobs

Wing Screws & Knobs -

Knurled Thumbscrews

Knurled Thumbscrews -

Control Handwheels

Control Handwheels -

Plastic & Rubber Grips

Plastic & Rubber Grips -

Roof Support Systems

Roof Support Systems -

Push Fit Knobs

Push Fit Knobs -

Fixings & Fasteners

Fixings & Fasteners

-

-

Adhesive Tapes

-

PTFE Tape

PTFE Tape -

Packing Tape

Packing Tape -

Fragile Tape

Fragile Tape -

Cloth Tape

Cloth Tape -

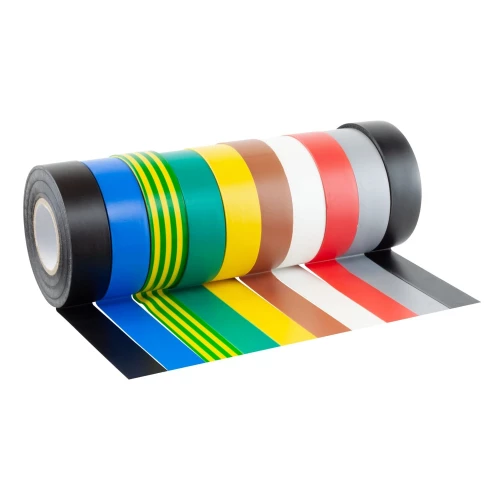

PVC Electrical Insulation Tape

PVC Electrical Insulation Tape -

Underground Cable Warning Tape

Underground Cable Warning Tape -

Floor Marking Tape

Floor Marking Tape -

Safety Hazard Warning Tape

Safety Hazard Warning Tape -

Non Slip Tape

Non Slip Tape -

Non-Adhesive Barrier Tape

Non-Adhesive Barrier Tape -

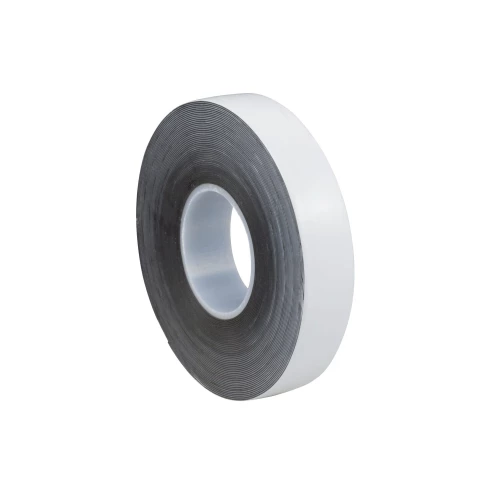

Double Sided Foam Tape

Double Sided Foam Tape -

Fleece Tape

Fleece Tape -

Self Amalgamating PVC Tape

Self Amalgamating PVC Tape -

Self Amalgamating Silicone Tape

Self Amalgamating Silicone Tape -

Self Amalgamating EPR Tape

Self Amalgamating EPR Tape -

Low Tack Paper Masking Tape

Low Tack Paper Masking Tape -

UV Resistant Blue Masking Tape

UV Resistant Blue Masking Tape

-

-

Panel Fasteners

-

School & Office Products

-

Rubber Seals

-

Business Services

- Terms and conditions

Frequently Asked Questions

What are serrated washers also known as?

Serrated washers are also commonly referred to as tooth washers due to the jagged tooth like serrations found on the surface of the inside or outside diameter of the washer. Another common term used to describe this style of washer is a shake proof washer. They could also be described by their DIN standards which are din6797j and din6797a for the internal and external toothed variations that we supply. Some people might simply call them tooth lock washers, due to the role that the serrations play in helping the washer to lock to the surface of its application.

Why are they also called shake proof washers?

The jagged tooth design of serrated washers acts as a locking mechanism that helps to make the washer resistant to loosening from vibrations, impact force or shaking. The serrations on the washer create friction as they drag against and bite into the surface that they are tightened into. They can be used to reduce the likelihood of a fastened bolt or nut from coming loose as a result of vibrations, shocks or movements within the application. Their ability to "shake proof" a fastened joint has earned them this moniker.

What are the two types of tooth lock washers?

There are two main types of serrated washers, internal tooth lock washers and external tooth lock washers. Internal tooth lock washers have serrated teeth on the inside hole of the washer, also known as its inner diameter. The external tooth lock washers have the serrations on the outside edge of the washer. Both types of serrated washers are designed to prevent the loosening of fasteners caused by vibrations, movement and other forces. Determining whether an internally or externally toothed washer is better for an application will depend on the type of fastener being used and the available space within the fastened joint. Internal tooth lock washers are often used with screws, while external tooth lock washers are commonly used with bolts.

What is a tooth washer used for?

Tooth washers are commonly used in the energy industry within power generation plants to secure heavy duty turbines and generators that are subjected to constant movement and vibration during operation. Serrated washers also have a use case in electronics, where they can be used to secure the fastening of components such as control panels, circuit breakers and junction boxes. Finally, the resistance to vibrations that tooth washers provide is generally very useful in the automotive industry. Serrated washers are often installed into car components such as engine mounts, suspension systems and brake assemblies. Tooth lock washers are essential in these applications for maintaining secure connections and preventing failure in parts that constantly vibrate and suffer micro-movements as a result of the combustion engine of a car.

Which way around do serrated washers go?

The jagged teeth on the outside or inside edge of serrated washers point towards a certain direction. This is because they are designed to bite into a particular surface during their application. For this reason, it is important to install tooth washers the right way around so that they can function as designed. Internal tooth lock washers were designed to bite into the underside of a fastener such as a screw head, bolt head or nut. This is because their primary task is to secure the fastener against vibrations and other forces that could cause it to loosen. So when installing an internally toothed washer you should always make sure that the serrated teeth point towards the fastening object that you want to secure, be it a screw head, bolt head or nut. External tooth lock washers work differently and have instead been designed to bite into the surface of the application that you are fastening. This means that when you install them, you should place the side with the teeth pointing up against the surface that you are bolting or screwing into. The teeth on externally serrated washers should not face towards the bolt head, screw head or nut. We know it can be confusing to know the correct use for washers in an application, so our team are happy to answer any questions. Feel free to use our contact us page for advice or help with installation.

How fast can I get my order?

Need your parts tomorrow? Our rapid same day dispatch has got you covered! Simply place your order before 4pm Mon-Thurs or 2pm Friday and select our Next Day Delivery service in the shopping cart. We also offer Guaranteed AM delivery when required, in addition to a Saturday delivery option.

If you don't mind waiting, we have a Free delivery method for orders over £30, and an economic £4.85 2nd Class delivery for orders between £10-£30.

Can I get a Free Sample?

Free Samples can be requested through our product pages, displayed in the sizing table beside the product you require. Please note you can always give us a call on 01233 713 581 or contact us on Live Chat to discuss samples.

Do I need to Sign Up for an account?

You do not need to sign up to place an order, but it is recommended if you'd like to gain loyalty points, giving discount off future orders. To learn more about loyalty points, please view our rewards scheme page.

I am not sure what parts I need?

If you're unsure which part you need then please do not hesitate to give one of our friendly Sales Team a call on 01233 713 581 and they can assist you. Alternatively, we're active on Live Chat during office hours. You can open this using the button in the bottom right corner of the website. Alternatively, you can write to us using our contact form.

Do you offer Returns on Products?

We offer a return period on all of our products to give you peace of mind, to view our policies and learn more about this process should it be required, please see our returns policy page.

Can you supply different colours of this product?

In most cases we have the facilities to offer you different colours of a product, specific to your requirements. Minimum order quantities may apply depending on the manufacturing technique in question, but please get in touch with any queries you may have.

Is there a minimum order value?

Please note that there is a minimum order value of £10 through our website (inclusive of VAT).

If you're new to our website you may want to check out our frequently asked questions section for answers to common customer queries.

What do these abbrievations mean?

While browsing the website you may come across abbreviations used for material names that you are unfamiliar with. You can find an explanation for these in our material abbreviations guide.

Vital Parts is rated 4.79 stars by Reviews.co.uk based on 1209 merchant reviews