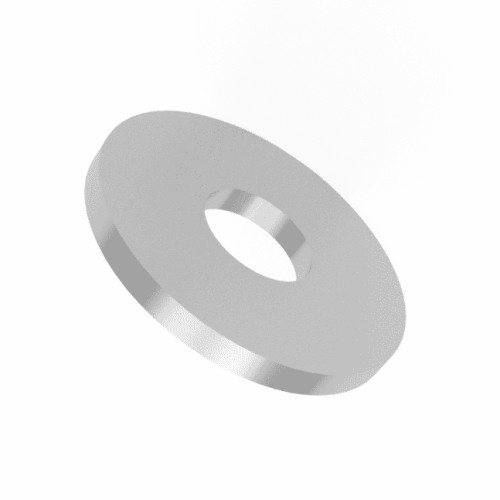

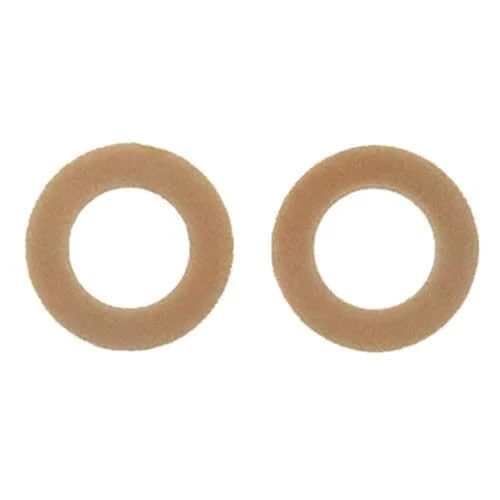

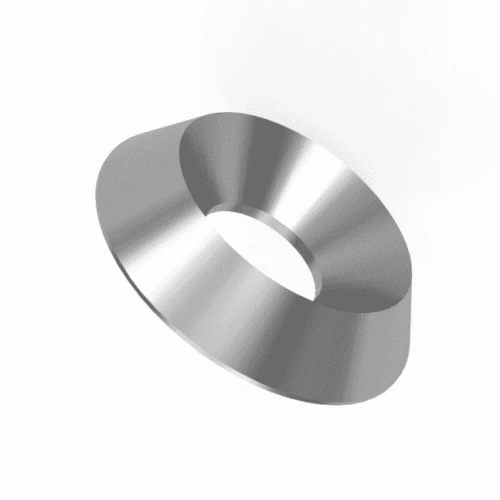

Stainless Steel Flat Washers

Stainless steel flat washers are indispensable components in almost any bolted joint. Designed to distribute the load of a threaded fastener (like a bolt or screw) evenly across a wider surface area, they prevent damage to the material being fastened and help ensure a secure, long-lasting connection. Without a flat washer, the concentrated force of a bolt head or nut could deform softer materials or even pull through the hole, compromising the integrity of your assembly.

You'll find flat washers in nearly every industry and application, from heavy construction and automotive manufacturing to delicate electronics and home DIY projects. They're crucial wherever you need to:

- Distribute Load: Spread the clamping force over a larger area, protecting the surface of the fastened material.

- Prevent Damage: Shield surfaces from the friction and wear caused by tightening nuts and bolts.

- Create Spacing: Act as a spacer between components.

- Improve Stability: Provide a smooth, consistent bearing surface for the fastener.

- Prevent Loosening: Though not a locking mechanism themselves, they improve the conditions for other locking methods (like lock washers) to work effectively.

Specific Applications of Stainless Steel Flat Washer Standards

Different flat washer standards exist to meet specific engineering requirements for dimensions, tolerances, and intended use.

DIN 125A Flat Washers

These are perhaps the most common and widely used general-purpose flat washers. They have a standard outer diameter and thickness relative to the bolt size, making them suitable for most everyday applications where a basic load distribution is needed.

- General Use: Machine building, automotive, furniture assembly, construction, and DIY projects.

- Wherever a standard-sized washer is sufficient to protect the surface and provide a bearing for the fastener.

DIN 433 Flat Washers (Small Series)

Unlike the DIN 125A, DIN 433 flat washers have a smaller outer diameter. This makes them ideal for applications where space is limited, or a more compact aesthetic is desired, without sacrificing too much load distribution.

- Electronics and Electrical Applications: Mounting circuit boards, securing smaller components where space is at a premium.

- Fine Mechanics: Precision instruments, delicate machinery where larger washers would interfere.

- Automotive Interior/Trim: Wherever a neat, less obtrusive fastening is required.

DIN 1052 Flat Washers (For Timber Constructions)

While not as universally used as 125A, DIN 1052 washers are specifically designed for timber constructions. They have a larger outer diameter and often a greater thickness than standard washers to provide a significantly larger bearing surface. This is crucial for wooden structures to prevent the bolt head or nut from compressing into or pulling through the softer wood material.

- Timber Framing: Securing beams, posts, and trusses in wooden buildings.

- Decking and Fencing: Providing robust connections in outdoor timber structures.

- Heavy Timber Connections: Ensuring the longevity and stability of large wooden assemblies.

DIN 9021 Flat Washers (Large Series / Fender Washers)

DIN 9021 flat washers are characterized by their very large outer diameter relative to the inner diameter. Often referred to as "fender washers," they offer maximum load distribution. This makes them essential when fastening soft or thin materials, or when covering oversized or damaged holes.

- Sheet Metal Work: Preventing fasteners from tearing through thin sheet metal panels.

- Plumbing and HVAC: Sealing connections or mounting components to soft insulation.

- Automotive Fenders and Body Panels: Hence the "fender washer" name.

- Repair Work: Covering existing large or elongated holes to allow for a secure fastening.

BS 4320 Flat Washers

The British Standard BS 4320 specifies dimensions for various types of metal washers for general engineering purposes. It includes different "types" (e.g., Type A for normal diameter, Type B for large diameter, Type C for small diameter) with specific thickness grades. While often similar to DIN standards, they provide alternatives for compatibility with British-engineered designs.

- General Engineering: Broad range of uses in British-designed machinery, vehicles, and structures.

- Maintenance and Repair: When replacing components in systems originally built to BS standards.

- Specific Industry Requirements: Certain sectors may still specify BS standards for consistency.

What is a Penny Washer?

A Penny Washer is an informal, colloquial term, primarily used in the UK, for a flat washer with a very large outer diameter relative to its inner diameter. It gets its name from the fact that its size is roughly comparable to an old penny coin.

Where is it used? Penny washers are used for the same reasons as DIN 9021 washers (which are the standardized version of this type of large washer). They are ideal for:

- Distributing extreme loads over soft materials like wood or plastic.

- Securing thin sheet materials without tearing.

- Covering oversized or irregular holes from previous fastenings or damage.

When to Use A2 and A4 Stainless Steel Washers

The choice between A2 and A4 stainless steel for your washers is crucial, as it dictates their resistance to corrosion and their suitability for different environments.

A2 Stainless Steel (Type 304):

- Common Use: This is the most widely used grade of stainless steel, offering excellent corrosion resistance in normal atmospheric conditions, freshwater, and general industrial environments.

- Applications: Fastening in kitchens, food processing equipment (dry areas), general machinery, outdoor furniture, and construction where exposure to salt or harsh chemicals is minimal.

- Cost-Effective: Generally more affordable than A4.

A4 Stainless Steel (Type 316 / "Marine Grade"):

- Superior Corrosion Resistance: This grade contains Molybdenum, which provides significantly enhanced resistance to pitting corrosion and corrosion from chlorides (salts) and various acids.

- Applications: Absolutely essential for marine environments (boats, docks, coastal structures), chemical processing plants, swimming pools, high-salinity areas, medical equipment, and food processing equipment where frequent harsh cleaning chemicals are used.

- Demanding Environments: Use A4 whenever there's exposure to saltwater, acids, or other highly corrosive substances.

Need help selecting the right washer for your applicatrion? Give us a call on 01233 713518

Categories

-

Plugs & Stoppers

-

Tapered Rubber Plugs

Tapered Rubber Plugs -

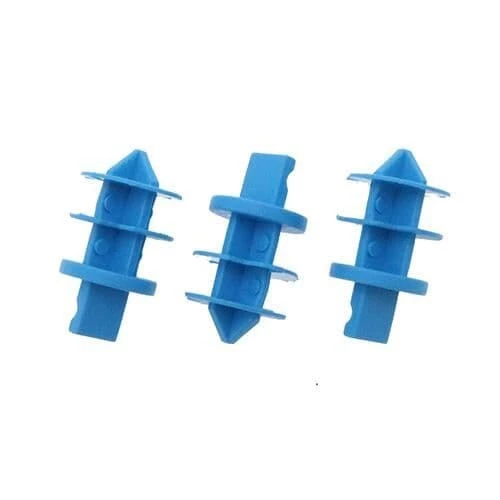

Silicone Ribbed Plugs

Silicone Ribbed Plugs -

Silicone Tapered Plugs

Silicone Tapered Plugs -

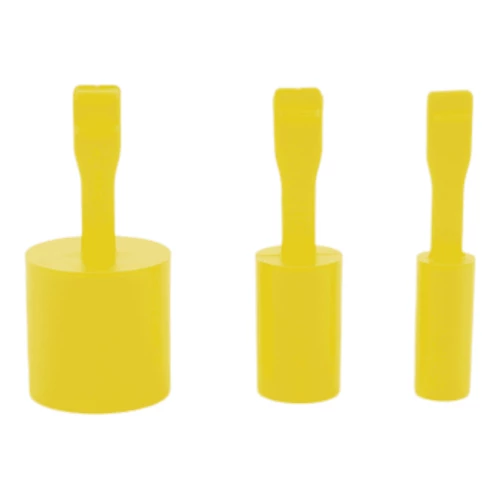

Silicone Plugs With Handle

Silicone Plugs With Handle -

Silicone Step Plugs

Silicone Step Plugs -

Silicone Pull Plugs

Silicone Pull Plugs -

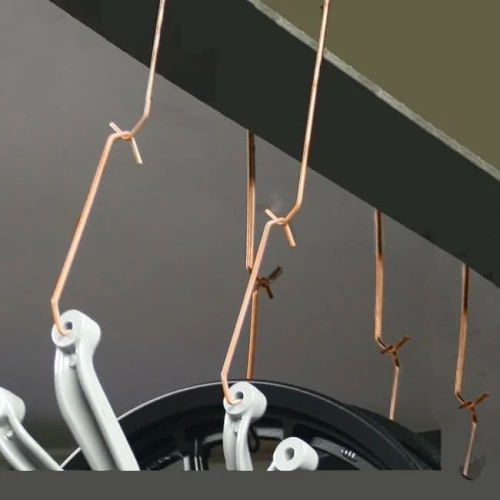

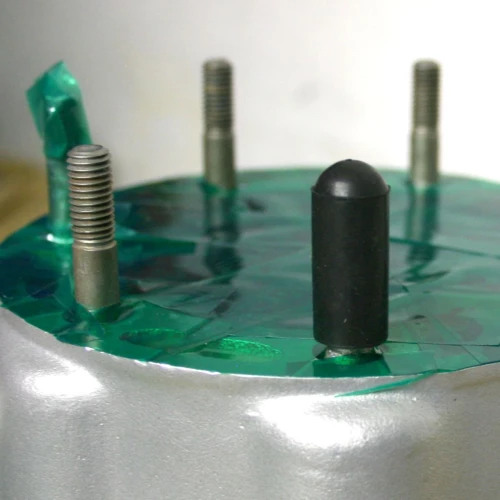

Silicone Thread Masking Plugs

Silicone Thread Masking Plugs -

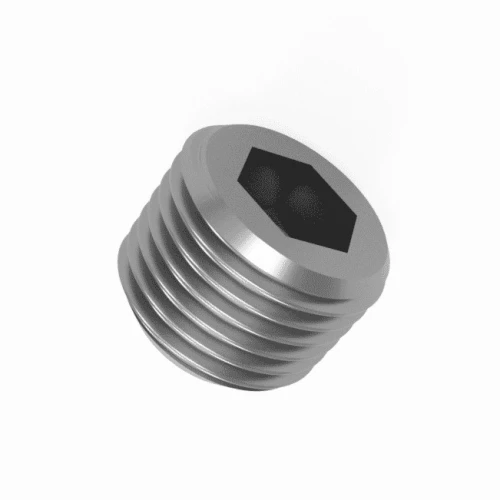

Threaded Plugs

Threaded Plugs -

Threaded Sealing Plugs

Threaded Sealing Plugs -

Cylindrical Pull Tab Plugs

Cylindrical Pull Tab Plugs -

Finned Pull Tab Plugs

Finned Pull Tab Plugs -

Fir Tree Plugs

Fir Tree Plugs -

Reversible Tapered Plugs

Reversible Tapered Plugs -

Round Tube Plugs

Round Tube Plugs -

Snap Fit Hole Plugs

Snap Fit Hole Plugs -

Stainless Steel Socket Pipe Plugs DIN 906

Stainless Steel Socket Pipe Plugs DIN 906 -

Door Stoppers

Door Stoppers -

Door Wedge

Door Wedge -

Finned Hole Plugs

Finned Hole Plugs -

Plastic End Plugs

Plastic End Plugs -

Ribbed Pipe End Plugs

Ribbed Pipe End Plugs -

Blanking Plugs

Blanking Plugs -

Ventilation Plugs

Ventilation Plugs -

Snap Fit Bushes

Snap Fit Bushes -

Liquid Tight Plugs

Liquid Tight Plugs -

Barrel Plugs

Barrel Plugs -

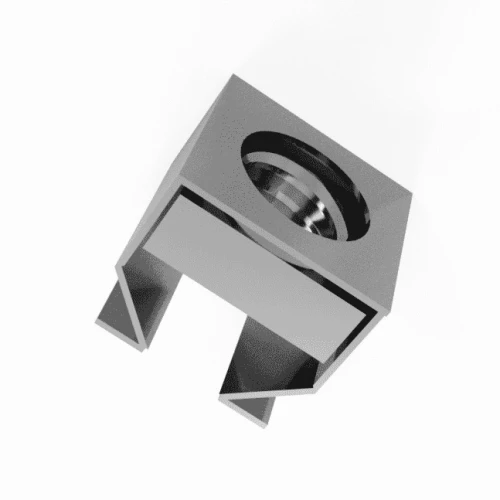

Washer Masking Plugs

Washer Masking Plugs -

Measurement Guide

Measurement Guide -

Silicone Flange Plugs

Silicone Flange Plugs -

Silicone Double Flange Plugs

Silicone Double Flange Plugs

-

-

Furniture & Chair Feet

-

Sofa Feet

Sofa Feet -

Screw In Furniture Feet

Screw In Furniture Feet -

Anti-Sink Feet

Anti-Sink Feet -

Round Ferrules

Round Ferrules -

Square Ferrules

Square Ferrules -

Walking Stick Ferrules

Walking Stick Ferrules -

Crutch Feet

Crutch Feet -

Push In Feet

Push In Feet -

Nail On Feet & Glides

Nail On Feet & Glides -

Office Chair and Furniture Castors

Office Chair and Furniture Castors -

Insert Glides

Insert Glides -

Saddle Feet

Saddle Feet -

Furniture & Chair Glides

Furniture & Chair Glides -

Stick On Feet & Pads

Stick On Feet & Pads -

School Chair & Furniture Feet

School Chair & Furniture Feet -

Fitting Guide

Fitting Guide

-

-

Adjustable Feet

-

Balance Feet

Balance Feet -

Anti-Vibration Levelling Feet

Anti-Vibration Levelling Feet -

Economic Adjustable Feet

Economic Adjustable Feet -

Slotted Head Adjustable Feet

Slotted Head Adjustable Feet -

Rubber Adjustable Feet

Rubber Adjustable Feet -

Stainless Steel Adjustable Feet

Stainless Steel Adjustable Feet -

Ready To Install Sets

Ready To Install Sets -

Weight Rated Articulated Feet

Weight Rated Articulated Feet -

Allen Key Adjustable Feet

Allen Key Adjustable Feet -

General Adjustable Feet

General Adjustable Feet -

Heavy Duty Tilting Feet

Heavy Duty Tilting Feet -

Tilting Adjustable Feet

Tilting Adjustable Feet -

Pozi Base Adjustable Feet

Pozi Base Adjustable Feet -

Polyamide Adjustable Feet

Polyamide Adjustable Feet -

One Piece Adjustable Feet

One Piece Adjustable Feet -

Metal Adjustable Feet

Metal Adjustable Feet -

Machinery Mounting Feet

Machinery Mounting Feet -

Threaded Fittings & Fixings

Threaded Fittings & Fixings -

Fitting Guide

Fitting Guide -

Low Profile Adjustable Feet

Low Profile Adjustable Feet -

Hexagon Base Feet

Hexagon Base Feet

-

-

Cable Management

-

Aluminium Cable Clips

Aluminium Cable Clips -

Rubber Grommets

Rubber Grommets -

Braided Cable Sleeving

Braided Cable Sleeving -

Cable Glands

Cable Glands -

PVC Cable Sleeving

PVC Cable Sleeving -

Spiral Cable Wrap

Spiral Cable Wrap -

Strain Relief

Strain Relief -

Nylon P Clips

Nylon P Clips -

Nylon P Clamps

Nylon P Clamps -

Cable Ties

Cable Ties -

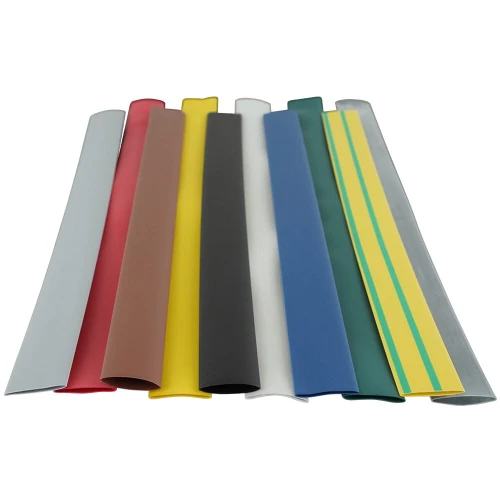

Heat Shrink Sleeves

Heat Shrink Sleeves -

Adhesive Lined Heatshrink

Adhesive Lined Heatshrink -

Cable Tie Mounts

Cable Tie Mounts -

Desk Cable Tidies

Desk Cable Tidies -

Velcro Cable Management

Velcro Cable Management -

Multi Cable Clips

Multi Cable Clips -

Plastic Grommet Strips

Plastic Grommet Strips -

Heat Shrink Caps

Heat Shrink Caps -

Rubber Grommet Strips

Rubber Grommet Strips

-

-

Bolts and Screws

-

Cheese Head Slotted Screws DIN 84

Cheese Head Slotted Screws DIN 84 -

Pipe Plugs

Pipe Plugs -

Hex Head Screws and Bolts

Hex Head Screws and Bolts -

Cap Screws

Cap Screws -

Button Screws

Button Screws -

Countersunk Screws

Countersunk Screws -

Pan Head Machine Screws

Pan Head Machine Screws -

Security Fasteners

Security Fasteners -

Screws for Plastic

Screws for Plastic -

Knurled Fasteners

Knurled Fasteners -

Grub Screws

Grub Screws -

Threaded Rod (All Thread)

Threaded Rod (All Thread) -

Weld Studs

Weld Studs -

Small Bolts

Small Bolts -

Stainless Steel Bolts By Metric Thread Size

Stainless Steel Bolts By Metric Thread Size -

Large Bolts

Large Bolts

-

-

Washers

-

Bonded Sealing Washers

Bonded Sealing Washers -

Standard Nylon Washers

Standard Nylon Washers -

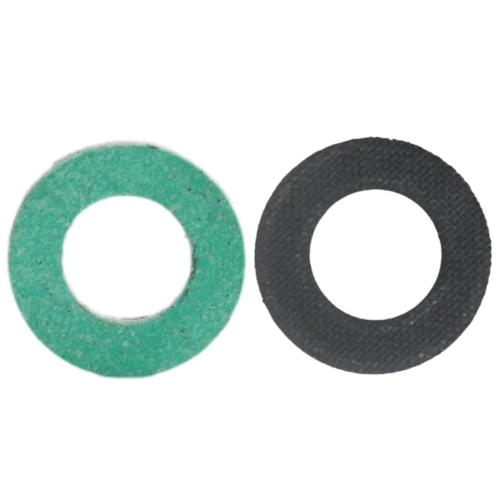

Rubber Washers

Rubber Washers -

Peek Washers

Peek Washers -

Silicone Washers

Silicone Washers -

Red Fibre Washers

Red Fibre Washers -

PTFE Washers

PTFE Washers -

FKM Washers

FKM Washers -

Anti-Loss Washers

Anti-Loss Washers -

Finishing Washers

Finishing Washers -

Headboard Washers

Headboard Washers -

Saddle Washers

Saddle Washers -

Stainless Steel Flat Washers

Stainless Steel Flat Washers -

Stainless Steel Spring Washers

Stainless Steel Spring Washers -

Stainless Steel Curved Washers

Stainless Steel Curved Washers -

Stainless Steel Serrated Washers

Stainless Steel Serrated Washers -

Stainless Steel Finishing Washers

Stainless Steel Finishing Washers -

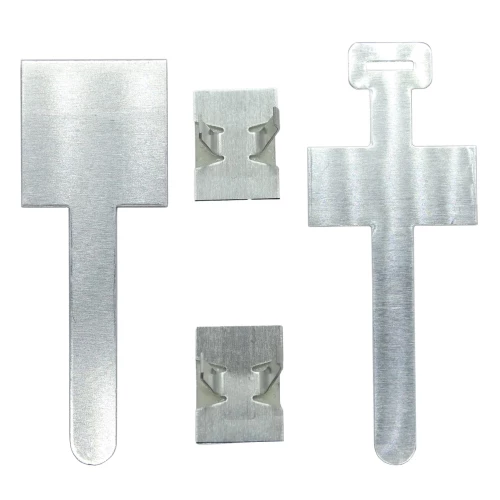

Stainless Steel Tab Washers

Stainless Steel Tab Washers -

WRAS Washers

WRAS Washers

-

-

Plastic & Nylon Fasteners

-

Industrial Hardware

-

General Handwheels

General Handwheels -

Door Bolts

Door Bolts -

Hinges

Hinges -

Latches

Latches -

Camlocks

Camlocks -

Index Plungers

Index Plungers -

Detent Pins

Detent Pins -

Furniture Fixings

Furniture Fixings -

Clamping Handles

Clamping Handles -

Bridge Handles

Bridge Handles -

Pull Handles

Pull Handles -

Ball Knobs

Ball Knobs -

Threaded Handwheels

Threaded Handwheels -

Wing Screws & Knobs

Wing Screws & Knobs -

Knurled Thumbscrews

Knurled Thumbscrews -

Control Handwheels

Control Handwheels -

Plastic & Rubber Grips

Plastic & Rubber Grips -

Roof Support Systems

Roof Support Systems -

Push Fit Knobs

Push Fit Knobs -

Fixings & Fasteners

Fixings & Fasteners

-

-

Adhesive Tapes

-

PTFE Tape

PTFE Tape -

Packing Tape

Packing Tape -

Fragile Tape

Fragile Tape -

Cloth Tape

Cloth Tape -

PVC Electrical Insulation Tape

PVC Electrical Insulation Tape -

Underground Cable Warning Tape

Underground Cable Warning Tape -

Floor Marking Tape

Floor Marking Tape -

Safety Hazard Warning Tape

Safety Hazard Warning Tape -

Non Slip Tape

Non Slip Tape -

Non-Adhesive Barrier Tape

Non-Adhesive Barrier Tape -

Double Sided Foam Tape

Double Sided Foam Tape -

Fleece Tape

Fleece Tape -

Self Amalgamating PVC Tape

Self Amalgamating PVC Tape -

Self Amalgamating Silicone Tape

Self Amalgamating Silicone Tape -

Self Amalgamating EPR Tape

Self Amalgamating EPR Tape -

Low Tack Paper Masking Tape

Low Tack Paper Masking Tape -

UV Resistant Blue Masking Tape

UV Resistant Blue Masking Tape

-

-

Panel Fasteners

-

School & Office Products

-

Rubber Seals

-

Business Services

- Terms and conditions