Pozi Countersunk Machine Screws DIN 965Z

Our DIN 965Z Pozi Countersunk Machine Screws are a versatile and reliable fastening solution, ideal for applications requiring a flush, neat finish. Available in a comprehensive range of sizes from M1.6 to M10, these screws cater to a wide variety of project requirements. Choose from two high-quality stainless steel grades: A2 stainless for excellent general corrosion resistance, or A4 stainless for enhanced resistance in more aggressive environments, such as marine or chemical applications.

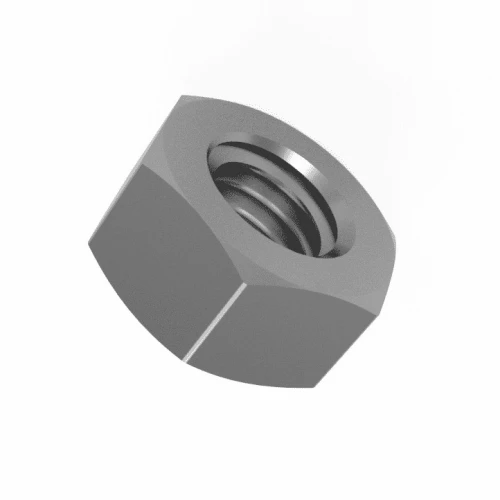

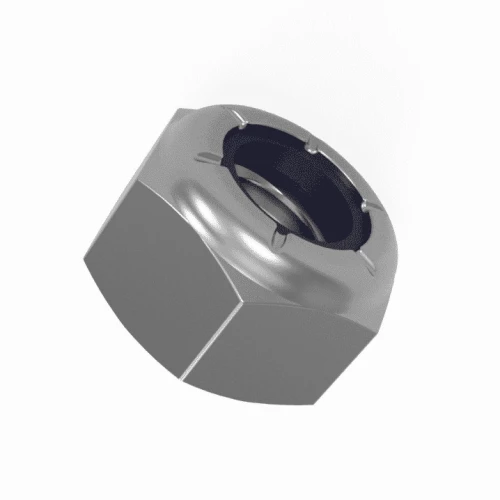

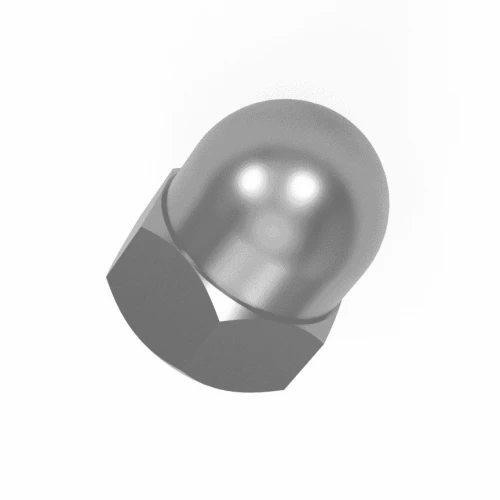

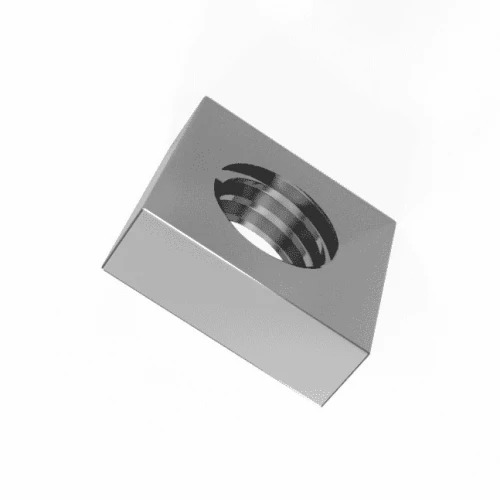

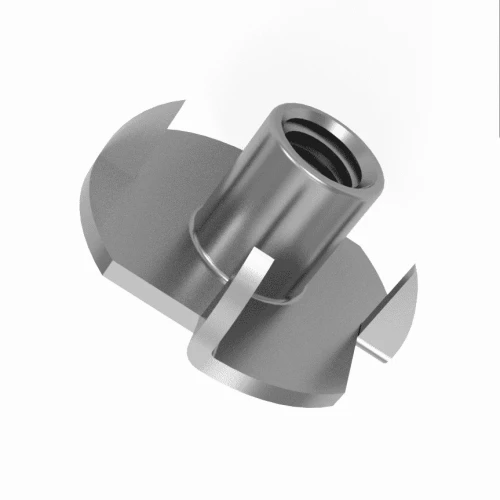

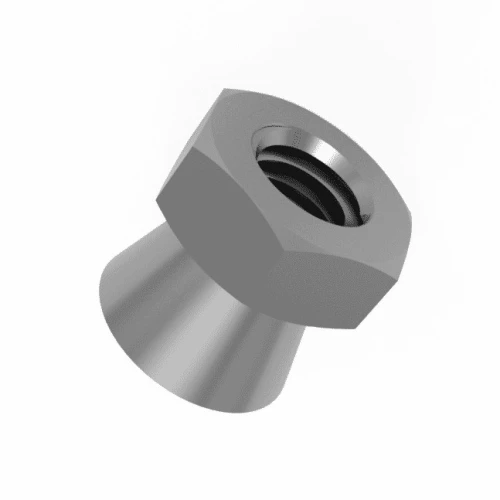

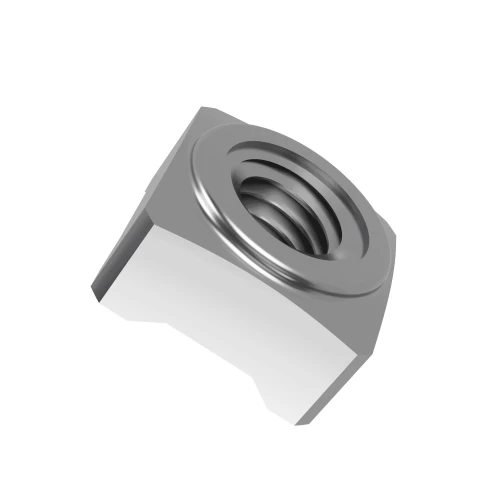

Most commonly used in conjunction with Washers and Nuts, these products pare used to hold fasteners in place, joining two or more parts together. We also offer Socket Head Screws and Hex Head Screws

Key Features:

- Countersunk Head: Designed to sit flush with the material surface, providing a smooth and professional finish, preventing snags and improving aesthetics.

- Pozi Drive: Offers improved cam-out resistance compared to traditional Phillips drives, ensuring more secure installation and reducing the risk of damage to the screw head or driver bit.

- Metric Threading (M1.6 - M10): Compatible with standard metric tapped holes and nuts, offering broad applicability.

- A2 & A4 Stainless Steel: Provides superior corrosion resistance, ensuring longevity and durability in various indoor and outdoor conditions.

How to install a countersunk screw:

Achieving a perfectly flush finish with DIN 965Z countersunk screws requires proper preparation:

- Pilot Hole Drilling: Drill a pilot hole in your material that is slightly smaller than the screw's major diameter. This provides a guide for the screw and prevents the material from splitting.

- Countersinking: Use a countersink bit to create a conical recess in the material. The countersink bit should match the angle of the screw head (typically 90 degrees for most countersunk screws).

- Depth Adjustment: Carefully adjust the depth of the countersink so that the screw head sits perfectly flush with the surface when fully tightened. It's often best to test on a scrap piece of material first.

- Driving the Screw: Use a Pozi drive screwdriver or bit that correctly fits the screw head. Apply firm, steady pressure while driving the screw to ensure it seats properly without stripping the head. Avoid overtightening, as this can damage the material or the screw.

Where are DIN 965Z Countersunk Screws Used?:

The flush finish and corrosion resistance of DIN 965Z Pozi Countersunk Machine Screws make them suitable for a wide array of applications, including:

- Furniture Assembly: Ideal for joining wooden or metal components where a smooth, snag-free surface is desired.

- Sheet Metal Work: Used in the assembly of enclosures, panels, and frames, providing a clean exterior.

- Marine Equipment: A4 stainless steel versions are perfect for boat fittings, deck hardware, and other marine applications due to their high resistance to saltwater corrosion.

- Electronic Enclosures: Securing covers and internal components in electronic devices, where a low-profile fastening is important.

- Architectural Fixtures: Mounting decorative panels, railings, and other fixtures where aesthetics are crucial.

- Kitchen and Bathroom Fittings: Excellent for securing handles, hinges, and other components due to their hygienic and corrosion-resistant properties.

- Automotive Interior Trim: Used in various interior applications where a flush and secure fastening is needed.

Categories

-

Plugs & Stoppers

-

Tapered Rubber Plugs

Tapered Rubber Plugs -

Silicone Ribbed Plugs

Silicone Ribbed Plugs -

Silicone Tapered Plugs

Silicone Tapered Plugs -

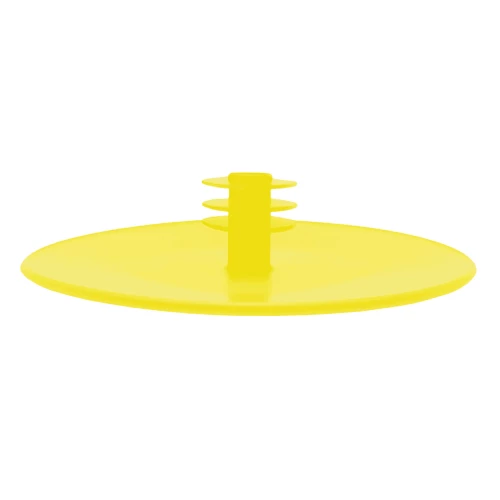

Silicone Plugs With Handle

Silicone Plugs With Handle -

Silicone Step Plugs

Silicone Step Plugs -

Silicone Pull Plugs

Silicone Pull Plugs -

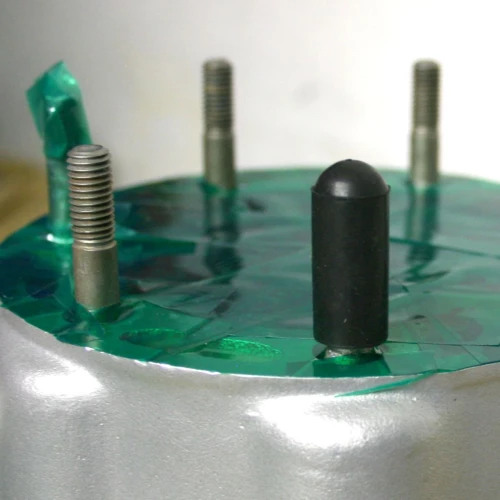

Silicone Thread Masking Plugs

Silicone Thread Masking Plugs -

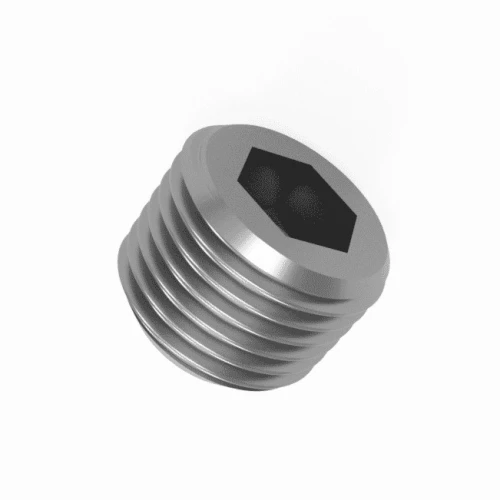

Threaded Plugs

Threaded Plugs -

Threaded Sealing Plugs

Threaded Sealing Plugs -

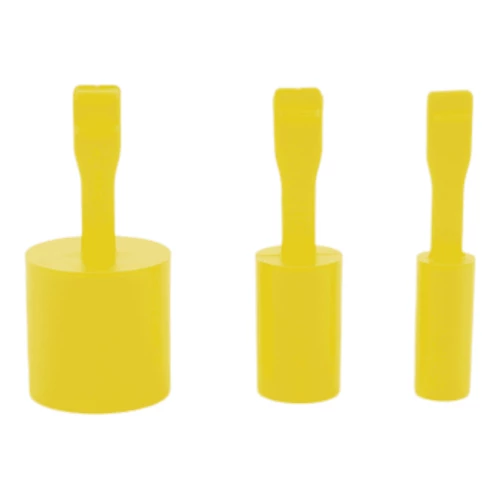

Cylindrical Pull Tab Plugs

Cylindrical Pull Tab Plugs -

Finned Pull Tab Plugs

Finned Pull Tab Plugs -

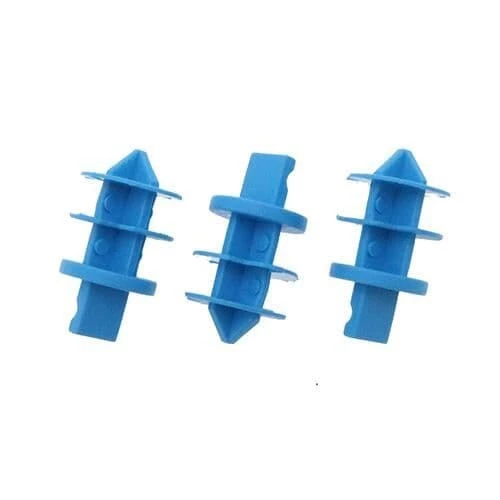

Fir Tree Plugs

Fir Tree Plugs -

Reversible Tapered Plugs

Reversible Tapered Plugs -

Round Tube Plugs

Round Tube Plugs -

Snap Fit Hole Plugs

Snap Fit Hole Plugs -

Stainless Steel Socket Pipe Plugs DIN 906

Stainless Steel Socket Pipe Plugs DIN 906 -

Door Stoppers

Door Stoppers -

Door Wedge

Door Wedge -

Finned Hole Plugs

Finned Hole Plugs -

Plastic End Plugs

Plastic End Plugs -

Ribbed Pipe End Plugs

Ribbed Pipe End Plugs -

Blanking Plugs

Blanking Plugs -

Ventilation Plugs

Ventilation Plugs -

Snap Fit Bushes

Snap Fit Bushes -

Liquid Tight Plugs

Liquid Tight Plugs -

Barrel Plugs

Barrel Plugs -

Washer Masking Plugs

Washer Masking Plugs -

Measurement Guide

Measurement Guide -

Silicone Flange Plugs

Silicone Flange Plugs -

Silicone Double Flange Plugs

Silicone Double Flange Plugs

-

-

Furniture & Chair Feet

-

Sofa Feet

Sofa Feet -

Screw In Furniture Feet

Screw In Furniture Feet -

Anti-Sink Feet

Anti-Sink Feet -

Round Ferrules

Round Ferrules -

Square Ferrules

Square Ferrules -

Walking Stick Ferrules

Walking Stick Ferrules -

Crutch Feet

Crutch Feet -

Push In Feet

Push In Feet -

Nail On Feet & Glides

Nail On Feet & Glides -

Office Chair and Furniture Castors

Office Chair and Furniture Castors -

Insert Glides

Insert Glides -

Saddle Feet

Saddle Feet -

Furniture & Chair Glides

Furniture & Chair Glides -

Stick On Feet & Pads

Stick On Feet & Pads -

School Chair & Furniture Feet

School Chair & Furniture Feet -

Fitting Guide

Fitting Guide

-

-

Adjustable Feet

-

Balance Feet

Balance Feet -

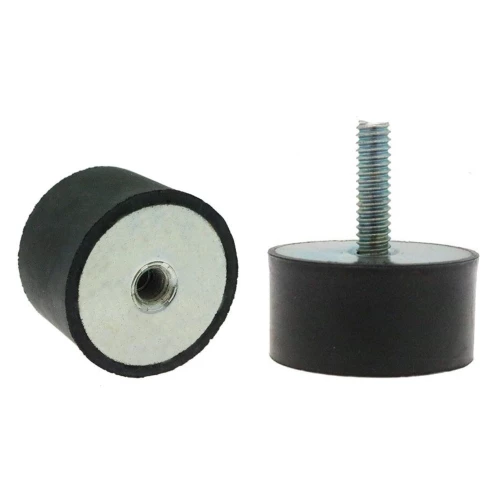

Anti-Vibration Levelling Feet

Anti-Vibration Levelling Feet -

Economic Adjustable Feet

Economic Adjustable Feet -

Slotted Head Adjustable Feet

Slotted Head Adjustable Feet -

Rubber Adjustable Feet

Rubber Adjustable Feet -

Stainless Steel Adjustable Feet

Stainless Steel Adjustable Feet -

Ready To Install Sets

Ready To Install Sets -

Weight Rated Articulated Feet

Weight Rated Articulated Feet -

Allen Key Adjustable Feet

Allen Key Adjustable Feet -

General Adjustable Feet

General Adjustable Feet -

Heavy Duty Tilting Feet

Heavy Duty Tilting Feet -

Tilting Adjustable Feet

Tilting Adjustable Feet -

Pozi Base Adjustable Feet

Pozi Base Adjustable Feet -

Polyamide Adjustable Feet

Polyamide Adjustable Feet -

One Piece Adjustable Feet

One Piece Adjustable Feet -

Metal Adjustable Feet

Metal Adjustable Feet -

Machinery Mounting Feet

Machinery Mounting Feet -

Threaded Fittings & Fixings

Threaded Fittings & Fixings -

Fitting Guide

Fitting Guide -

Low Profile Adjustable Feet

Low Profile Adjustable Feet -

Hexagon Base Feet

Hexagon Base Feet

-

-

Cable Management

-

Aluminium Cable Clips

Aluminium Cable Clips -

Rubber Grommets

Rubber Grommets -

Braided Cable Sleeving

Braided Cable Sleeving -

Cable Glands

Cable Glands -

PVC Cable Sleeving

PVC Cable Sleeving -

Spiral Cable Wrap

Spiral Cable Wrap -

Strain Relief

Strain Relief -

Nylon P Clips

Nylon P Clips -

Nylon P Clamps

Nylon P Clamps -

Cable Ties

Cable Ties -

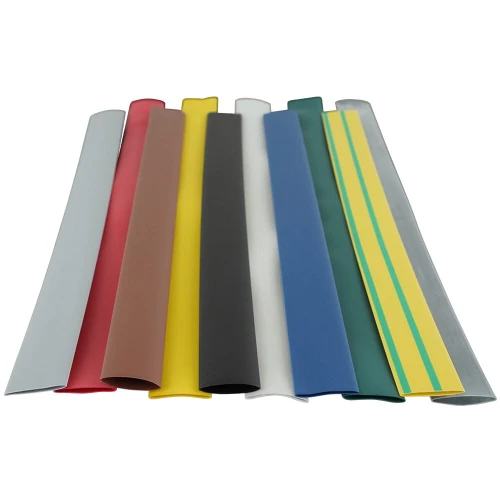

Heat Shrink Sleeves

Heat Shrink Sleeves -

Adhesive Lined Heatshrink

Adhesive Lined Heatshrink -

Cable Tie Mounts

Cable Tie Mounts -

Desk Cable Tidies

Desk Cable Tidies -

Velcro Cable Management

Velcro Cable Management -

Multi Cable Clips

Multi Cable Clips -

Plastic Grommet Strips

Plastic Grommet Strips -

Heat Shrink Caps

Heat Shrink Caps -

Rubber Grommet Strips

Rubber Grommet Strips

-

-

Bolts and Screws

-

Cheese Head Slotted Screws DIN 84

Cheese Head Slotted Screws DIN 84 -

Pipe Plugs

Pipe Plugs -

Hex Head Screws and Bolts

Hex Head Screws and Bolts -

Cap Screws

Cap Screws -

Button Screws

Button Screws -

Countersunk Screws

Countersunk Screws -

Pan Head Machine Screws

Pan Head Machine Screws -

Security Fasteners

Security Fasteners -

Screws for Plastic

Screws for Plastic -

Knurled Fasteners

Knurled Fasteners -

Grub Screws

Grub Screws -

Threaded Rod (All Thread)

Threaded Rod (All Thread) -

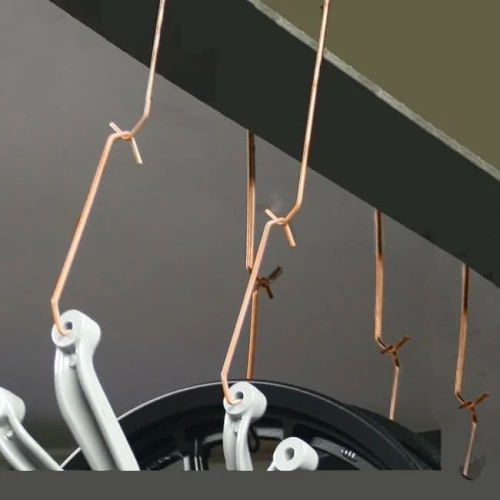

Weld Studs

Weld Studs -

Small Bolts

Small Bolts -

Stainless Steel Bolts By Metric Thread Size

Stainless Steel Bolts By Metric Thread Size -

Large Bolts

Large Bolts

-

-

Washers

-

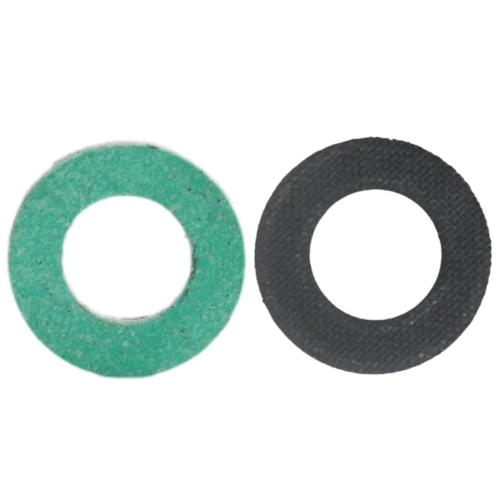

Bonded Sealing Washers

Bonded Sealing Washers -

Standard Nylon Washers

Standard Nylon Washers -

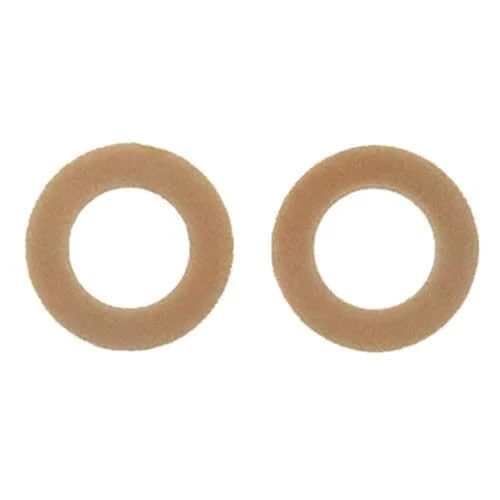

Rubber Washers

Rubber Washers -

Peek Washers

Peek Washers -

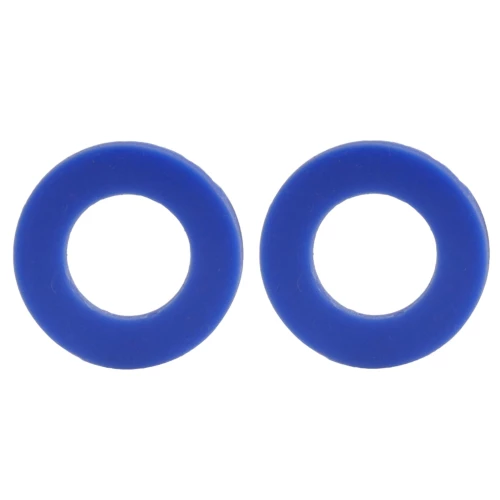

Silicone Washers

Silicone Washers -

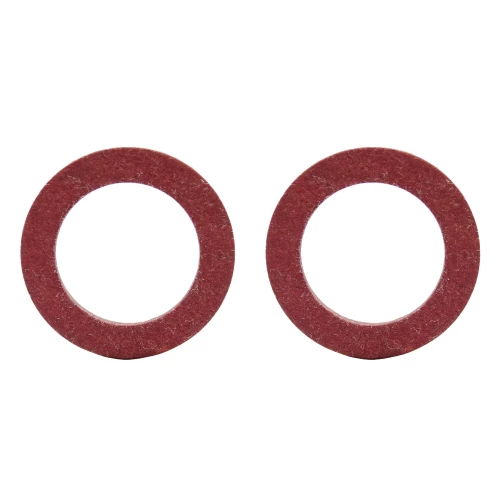

Red Fibre Washers

Red Fibre Washers -

PTFE Washers

PTFE Washers -

FKM Washers

FKM Washers -

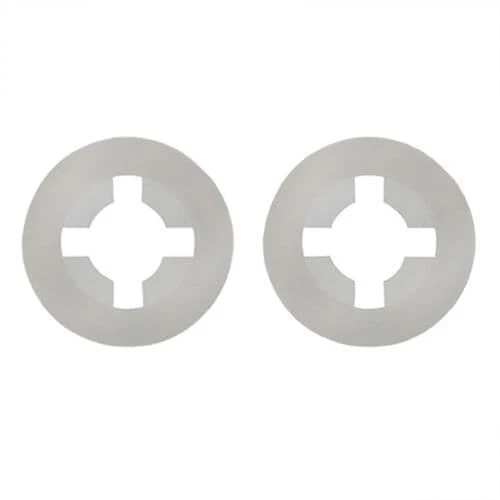

Anti-Loss Washers

Anti-Loss Washers -

Finishing Washers

Finishing Washers -

Headboard Washers

Headboard Washers -

Saddle Washers

Saddle Washers -

Stainless Steel Flat Washers

Stainless Steel Flat Washers -

Stainless Steel Spring Washers

Stainless Steel Spring Washers -

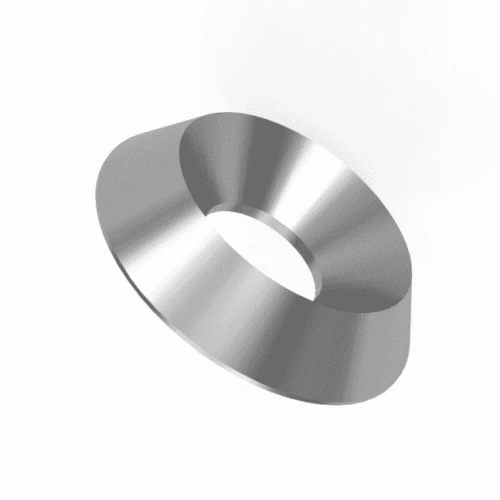

Stainless Steel Curved Washers

Stainless Steel Curved Washers -

Stainless Steel Serrated Washers

Stainless Steel Serrated Washers -

Stainless Steel Finishing Washers

Stainless Steel Finishing Washers -

Stainless Steel Tab Washers

Stainless Steel Tab Washers -

WRAS Washers

WRAS Washers

-

-

Plastic & Nylon Fasteners

-

Industrial Hardware

-

General Handwheels

General Handwheels -

Door Bolts

Door Bolts -

Hinges

Hinges -

Latches

Latches -

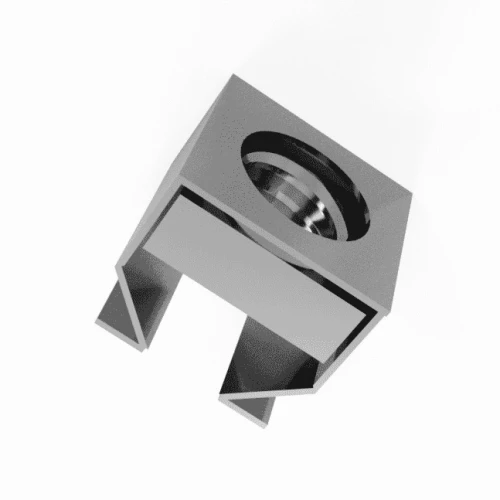

Camlocks

Camlocks -

Index Plungers

Index Plungers -

Detent Pins

Detent Pins -

Furniture Fixings

Furniture Fixings -

Clamping Handles

Clamping Handles -

Bridge Handles

Bridge Handles -

Pull Handles

Pull Handles -

Ball Knobs

Ball Knobs -

Threaded Handwheels

Threaded Handwheels -

Wing Screws & Knobs

Wing Screws & Knobs -

Knurled Thumbscrews

Knurled Thumbscrews -

Control Handwheels

Control Handwheels -

Plastic & Rubber Grips

Plastic & Rubber Grips -

Roof Support Systems

Roof Support Systems -

Push Fit Knobs

Push Fit Knobs -

Fixings & Fasteners

Fixings & Fasteners

-

-

Adhesive Tapes

-

PTFE Tape

PTFE Tape -

Packing Tape

Packing Tape -

Fragile Tape

Fragile Tape -

Cloth Tape

Cloth Tape -

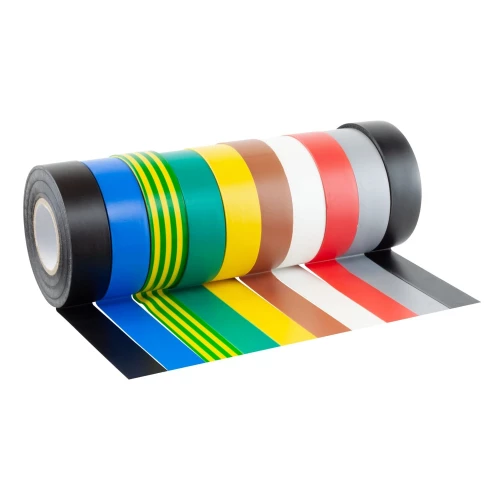

PVC Electrical Insulation Tape

PVC Electrical Insulation Tape -

Underground Cable Warning Tape

Underground Cable Warning Tape -

Floor Marking Tape

Floor Marking Tape -

Safety Hazard Warning Tape

Safety Hazard Warning Tape -

Non Slip Tape

Non Slip Tape -

Non-Adhesive Barrier Tape

Non-Adhesive Barrier Tape -

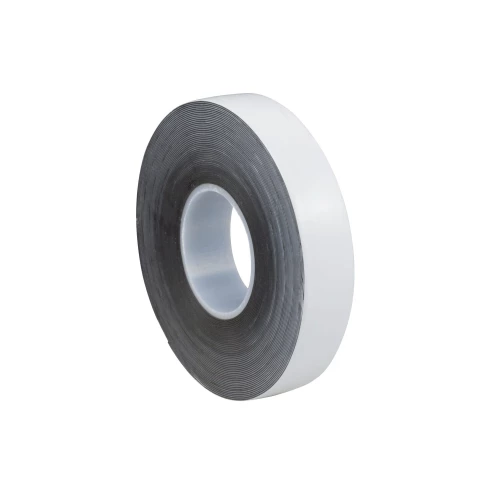

Double Sided Foam Tape

Double Sided Foam Tape -

Fleece Tape

Fleece Tape -

Self Amalgamating PVC Tape

Self Amalgamating PVC Tape -

Self Amalgamating Silicone Tape

Self Amalgamating Silicone Tape -

Self Amalgamating EPR Tape

Self Amalgamating EPR Tape -

Low Tack Paper Masking Tape

Low Tack Paper Masking Tape -

UV Resistant Blue Masking Tape

UV Resistant Blue Masking Tape

-

-

Panel Fasteners

-

School & Office Products

-

Rubber Seals

-

Business Services

- Terms and conditions